|

|

Post by mlehman on Oct 14, 2014 11:38:33 GMT -8

I use wire nuts for most connections under the layout. They're proven to be reliable, easy to use, easy to inspect, and make reconfiguring wiring easy. And short of using nails and wrapping the wires around them, I can't think of a cheaper way to make the connections needed in model railroading.

Strangely, you only rarely hear about anyone using wirenuts in the model press, as common and easily available as they are, not to mention the fact that we've all used them before. And if they're good enough for 110 volts, why not for our hobby uses?

Tom's post of the pics of Mr. Perrins magnificent scenically un-compressed Illinois Central layout showed at least one other layout -- albeit a much larger one -- than mine using wire nuts. I rather doubt this is an experimental installation. Those are trusted connectors to be in use on a project this size. It's no place for wiring do-overs.

So I've admitted I'm a wire nutaholic. Anyone else? I created a poll, all in good fun of course. I'm not insisting there's nuttin' better, but that the wire nut is a useful thing that has often been neglected among the options in layout wiring.

Please add your comments and experiences. I believe the humble wire nut speeds up construction and wiring and have found not real drawbacks. From time to time, yes, there are things I used different connectors for, but wire nuts make up well over 90% of what I use now for non-soldered wiring.

|

|

|

|

Post by edwardsutorik on Oct 14, 2014 11:51:08 GMT -8

I've been an electrician since the '70's. So I've put many thousands of wire nuts on wires. PROPERLY INSTALLED, I have no doubt they'll do the job.

On my modules (Freemo), I don't use them.

I think it's because I view layout wiring as closer to electronics rather than electrical. And wire nuts in electronics are stunningly rare.

I use mostly barrier strips for wire connections. That's partly because I figure I'll probably have to unconnect/reconnect. And wire nuts are really not so good at that. While I do do that, the "old" wire ends get pretty chewed up and twisted. Given a chance, I'll cut the wire nuts off and redo the whole connection.

And barrier strips and tie wraps under the module look SO professional--something hard to achieve with wire nuts. And those "suitcase" connectors don't look much better.

And, with barrier strips, it's easy to put a voltmeter on a connection. With those other things, not so much.

So, go figure. An electrician who uses them all the time at work, but has yet to use them on a layout.

Ed

PS: I didn't vote.

|

|

|

|

Post by mlehman on Oct 14, 2014 13:02:10 GMT -8

Ed,

Modules are a place where the logic of going to the trouble and expense of using more complex methods still makes a lot of sense. Especially in ones that will be moved frequently, where snagging and other issues could arise.

Your mention of differentiating between electrical and electronic wiring methods is a great observation. I know some of the differences are practical, but I suspect a lot of it is cultural. It's just how something is done. After years of reading about and seeing pics of wiring, we are left with a pretty vivid image of what wiring is supposed to look like under a layout.

But other than in magazine articles, how much time is spent admiring the wiring under the layout? Once it's running, virtually none.

Which is what led me to wire nuts in the first place. I started off with barrier strips and crimp-on terminals. Not only did the costs add up, the crimp terminals were unreliable even when care was taken to install properly. I sure wasn't going to solder all of them down under there so I could insert them into the barrier strips sans terminal and leaving them just twisted was a bad idea...

Then it hit me, just use a wire nut. From then on the last 75% of my layout wiring was done mostly with wire nuts. I combine that with a system of wire ID and it's really pretty simple to analyze faults.

But people should wire in the way they feel comfortable with. My only real concern are those folks who start a layout and then find the wiring gets the best of them just in terms of the hardware and time factors. Wire nuts are simply another way of doing what model railroaders have always done.

|

|

|

|

Post by edwardsutorik on Oct 14, 2014 13:58:45 GMT -8

But other than in magazine articles, how much time is spent admiring the wiring under the layout? Once it's running, virtually none. I dunno. Every time I set up, Harry Wong crawls underneath and takes pictures. I use a lot of crimp terminals. I NEVER use the insulated ones--I don't trust them--always the uninsulated. And I use the special tool that is only for uninsulated. I have NEVER had a crimp-on fail. Done right, the wire is practically welded to the connector. Ed |

|

|

|

Post by Paul Cutler III on Oct 14, 2014 15:17:23 GMT -8

I don't like wire nuts for a layout. I don't like they way they look. I don't like the temporary nature of them. I don't like how they can fall off. I don't like the way they snag on things. Give me barrier strips (the Euro kind, too), solder connections, or suitcase connectors before wire nuts.

Spade lug crimps, insulated or not, work just fine with the right tool (a ratcheting type). One fellow I know complained about his crimps not working properly. When he showed me how he was doing them, he was inserting the lugs backwards into the crimp tool.

|

|

|

|

Post by edwardsutorik on Oct 14, 2014 16:00:12 GMT -8

I don't like how they can fall off. A properly installed wire nut cannot fall off (unless it is junk). Wire nuts have a spiral cone shaped spring inside. Most are made these springs are made of square cross-sectioned wire. So, when you thread them on, the square section sort of cuts threads into the wires as it screws on. In addition, the spring maintains compression tension of the assembly. I HAVE had a few wire nuts "fall off". It's awfully embarrassing. 'Cause I made a, er, um, mistake. Er, um. Putting the darn things on isn't always as easy as it should be. But, since I'm a pro-fessional, I do it over until it's right. And then, the nut will not fall off. Ed |

|

|

|

Post by alcoc430 on Oct 14, 2014 16:02:20 GMT -8

Aren't wire nuts problematic for all stranded wire connections? That would be my issue with them. Plus IMHO for wire under the layout these connections would be floating so you would have to tape them to prevent the nuts from getting knocked off when you are craweling around then the tape would make it a pain to troubleshoot or other work.

|

|

|

|

Post by mlehman on Oct 14, 2014 16:43:50 GMT -8

Ed, The crimp-ons I used were the plain uninsulated spade terminals and the appropriate tool. Generally, I got to where I could get them on reliably, after a false start or two, but it seemed like more trouble than it was worth for a connection that, in most cases, would never be touched again until after it's long past mattering to me. Aren't wire nuts problematic for all stranded wire connections? That would be my issue with them. Plus IMHO for wire under the layout these connections would be floating so you would have to tape them to prevent the nuts from getting knocked off when you are craweling around then the tape would make it a pain to troubleshoot or other work. The issue with stranded wire applies to their ordinary use. They don't want any strands escaping enough to be a surprise if energized and there's some issue that they might loosen if heated by power flowing through the connection. Not too relevant to model railroading use. I've never had an issue with knocking them loose. The way I wire them leaves things tucked up against the bottom of the bench work. Sometimes I have some extra length, then I just tie a knot on the wires, then wirenut the ends together. I have taped them in wiring houses where that seemed necessary, but haven't under the layout. The only issues I've had is in doing some structure wiring with some real light wire (30 ?) where two strands in the little gray wirenuts is sometimes not enough to engage the coil inside, so the don't tighten. I then will just double over the wires and that usually tightes up things right. |

|

|

|

Post by edwardsutorik on Oct 14, 2014 16:53:16 GMT -8

Aren't wire nuts problematic for all stranded wire connections? That would be my issue with them. I use them frequently to connect various quantities of #12 stranded on up. I've experienced no particular problems. When you put wire nuts on, you should keep "winding" them until the wires coming into the wire nut are also twisted together (besides the stripped wire inside the wire nut). I've long ago gone over to wing nuts, as I can tighten them more. There are also various wing nut runners that you can get to make your life more pleasant. If the wire nuts are put on properly, you can't knock them off. You'll more likely rip some wires out of something. You clumsy thing. That said, wiring should never be hanging down so it can get snagged. If you do that, you'll get what you deserve. Also, I see no need to wrap up wire nuts with tape. The stripped wire should be entirely inside the wire nut, so there's no benefit. Plus, when you want to take the wire nut off, everything is tape-sticky. Ed |

|

|

|

Post by Gary P on Oct 15, 2014 5:45:17 GMT -8

Interesting poll. I have not used them for MR work yet, but will definitley consider it in the future.

|

|

|

|

Post by riogrande on Oct 15, 2014 6:43:20 GMT -8

There is no option in the poll for "I don't have a clue what your talking about" so I didn't participate.

So well, that's my response since I am not sure what these wire nuts are so I don't know why they would be good or the work of the devil. I prefer salty nuts myself, cashews and peanuts mainly.

|

|

|

|

Post by canrailfan on Oct 15, 2014 6:52:27 GMT -8

I've used wire nuts in the 'draft' stage of layout wiring, to get trains running sooner. Once the layout is up and running, I have gone back and made the wiring more 'permanent' with barrier strips and crimp on spade lugs, etc. I usually find I can simplify the wiring in some places on this second pass, I guess the urge to get the trains running means not always thinking out the best way to hook up that latest piece of the trackwork first time around.

Spade lugs (insulated or non-insulated) come in many different quality levels. It doesn't pay to buy the cheapest, I did that once on the well-known auction site. The terminals that came were paper-thin metal, even professional crimping tools couldn't make a secure connection with them. I've never had a good quality crimped-on lug come loose.

I've also put in some of the connector strips with the screws on top that clamp down on wires inserted on the sides. These seem to be working okay but they're a bit more expensive than the barrier strips. Not having to put spade lugs on the wires helps even out the cost and does speed up installation however.

David

|

|

|

|

Post by kentuckysouthernrwy on Oct 15, 2014 7:05:50 GMT -8

I've pretty much soldered most everything on my layout. I've dabbled with the 'suitcase' connectors with mixed results and given up on them for the future. Don't look under my layout, I'm not a wiring artist by any means.

I am open to the suggestion that this thread has made.

|

|

|

|

Post by mlehman on Oct 15, 2014 8:03:01 GMT -8

There is no option in the poll for "I don't have a clue what your talking about" so I didn't participate. So well, that's my response since I am not sure what these wire nuts are so I don't know why they would be good or the work of the devil. I prefer salty nuts myself, cashews and peanuts mainly. Jim, Good one. Guess I assumed people were familiar with wire nuts, but here's a pic:  A couple of them are actually "wing nuts." No, not the folks on your Ignore list, but the wings help tighten them up and make the easier to manipulate and less prone to rolling away when placed on a surface. The small gray one, the yellow and the red all have their uses. The nice thing is if you have a connection where the number of wires keeps growing, like with my structure lighting projects, you just use the next bigger one to raise the capacity when you attach new wires. I've used wire nuts in the 'draft' stage of layout wiring, to get trains running sooner. Once the layout is up and running, I have gone back and made the wiring more 'permanent' with barrier strips and crimp on spade lugs, etc. I usually find I can simplify the wiring in some places on this second pass, I guess the urge to get the trains running means not always thinking out the best way to hook up that latest piece of the trackwork first time around.SNIP David David, Thanks for that great suggestion! Even if you're not up for a long term commitment, the wire nut is definitely up to being a humble placeholder. Yes, the first draft of anything can be messy. The wire nut makes it possible to quickly revise wiring, whether or not you use them for a permanent installation. |

|

|

|

Post by steveturner on Oct 15, 2014 8:24:32 GMT -8

Well if its the work of the devil your house is devilish.Light fixtures and general wireing house wise your home is full of them. Bottom line same goes with suitcase connectors if you use the correct size for wireing at hand all should be fine.I believe quite often color dictates number and size of wire that the connector can hold. Sloppy work is probably the biggest reason for failure and wrongsize of connector being used. There are many ways to wire up your MR. Its all what your comfortable with, how neat you want tobe, how much you want to spend, how much time you want to spend on it, whats available to you and whether you want to sleep at night or not LOL. Personally i use buss bars from old house fuse panels as main routing and say feeding yards and suitcase connector for feeders off of main 14 gauge stranded buss line around layout. The finer points of wireing a layout could be discussed and argued untile you are blue in the face.Its your RR, do what you feel fits good for you and works for you. Personally if i was in a damp basement etc i would be concerned more about that than wire nuts............the dampness probably will turn your copper wires green! Steve

|

|

|

|

Post by valenciajim on Oct 15, 2014 11:21:20 GMT -8

I use barrier strips to connect my wiring. I am happ ywitht her esult and will continue to use them. I found the best prices for barrier strips are from Radio Shack.

|

|

|

|

Post by riogrande on Oct 15, 2014 11:28:44 GMT -8

Thanks for the education Mike. I have used those things in the picture for house old wire splicing where they were usually already installed - as Steve Tuner pointed out. That's the only place I can really recall seeing those commonly used - and I have used them myself in that setting only.

When I first saw the term wire nuts, the only thing I could imagine were those nuts you see on light airplane engines which have wires run through them to keep them from coming unscrewed and falling out! Those look like wired nuts to me! I simply couldn't imagine those being used on a train layout and if they were, those would be evil!

So far the only wiring I've done is wires attached via traditional screw terminals, soldered or the suite case wire taps, which recently people have recommended against in a modular club as unreliable.

|

|

|

|

Post by oldmuley on Oct 15, 2014 16:39:34 GMT -8

Your poll needs a 7th choice- no interest in using them. I use screw terminals almost exclusively.

|

|

|

|

Post by Paul Cutler III on Oct 15, 2014 16:44:28 GMT -8

Steve,

Yes, my house is full of wire nuts, but they are all inside junction boxes where they belong. When used properly inside a junction box, wire nuts are great. Outside a junction box...not so much.

|

|

|

|

Post by mlehman on Oct 15, 2014 19:07:58 GMT -8

Thanks for the education Mike. I have used those things in the picture for house old wire splicing where they were usually already installed - as Steve Tuner pointed out. That's the only place I can really recall seeing those commonly used - and I have used them myself in that setting only. When I first saw the term wire nuts, the only thing I could imagine were those nuts you see on light airplane engines which have wires run through them to keep them from coming unscrewed and falling out! Those look like wired nuts to me! I simply couldn't imagine those being used on a train layout and if they were, those would be evil! So far the only wiring I've done is wires attached via traditional screw terminals, soldered or the suite case wire taps, which recently people have recommended against in a modular club as unreliable. Jim, I figured you'd know 'em when you see them. Ah, the airplane ones. Generally, such a nut is called a castellated nut, because it looks like a turret on a castle from the cuts where the safety wire can pass through. I think the wire is just "safety wire" in common usage, but there's probably a better technical term. Suit case taps or IDCs (for I-something Displacement Connector) have been a long subject of controversy in the hobby. People either swear by them or swear at them. They work, if properly installed, except that tends to be a little more tricky than operating a wire nut... But wire nuts have been all but unmentionable as far as I can tell, so evil they can't be discussed in polite company apparently. So I thought it was time to admit my own helplessness in the face of their cheapness, ease of use, and reliability. If you have all three, you're good in my book. And the poll is pretty evenly divided, which actually surprises me. I figured the negatives would run to about 80%, so I figure we're doing good at around half and half. We really are becoming a more tolerant hobby  Maybe this explains for OldMuley why the only negative choice. I figured "work of the devil" would pretty much cover it. But maybe I should have had a "No, What? Me Worry?" Alfred E. Neumann response?  |

|

|

|

Post by riogrande on Oct 16, 2014 3:30:03 GMT -8

Well, here is a thought I had on wire nuts, now that I know the proper term. My "common sense" uneducated opinion is that they work best on large solid strand wire like houses have, so that is the convention.

Train layouts typically use much smaller gauge wire which includes stranded wire, so it makes sense to me why people would NOT use wire nuts very much, or at all, on train layout wiring. For those reasons, it has never occurred to me to used them, and after this discussion, I still think my feelings on this haven't changed. I can't think of many articles in train magazines where I have seen them either, although I'm sure someone could dig up examples.

For me, when I twist wires together, usually solder them and then wrap them with black electrical tape to protect them from shorting - but I'm cheap and old fashioned. Those shrink connectors are just something else I have to go spend money on although they are slick for sure, I can do the same thing with a couple layers of black electrical tape.

So my vote still goes to the poll option that isn't on the poll: no I don't used them, they aren't the work of the devil, they are for house wiring and that's where I will continue to use them.

|

|

|

|

Post by mlehman on Oct 16, 2014 4:50:12 GMT -8

Well, here is a thought I had on wire nuts, now that I know the proper term. My "common sense" uneducated opinion is that they work best on large solid strand wire like houses have, so that is the convention. Train layouts typically use much smaller gauge wire which includes stranded wire, so it makes sense to me why people would NOT use wire nuts very much, or at all, on train layout wiring. For those reasons, it has never occurred to me to used them, and after this discussion, I still think my feelings on this haven't changed. I can't think of many articles in train magazines where I have seen them either, although I'm sure someone could dig up examples...SNIP Jim, Well, I never said wire nuts are a better connection, just that the work just as well as the common methods. On things like this you either can be a part of the crowd -- or out in front of the mob...  Just to reassure those of us one step ahead of the pitchforks and cudgels, I took a look to confirm that wire nuts are rated in model railroad friendly terms, NOT strictly in electrical code use -- although as has been mentioned, if it's good enough for 110 volts, it's likely way overrated for use on the layout... The wire nut color code tells you roughly what it covers in terms of gauge and number of wires it can handle. The one in use in the largest numbers are the red, yellow, and gray in descending size order. There are blue and orange ones that fall in between the gray and yellow ones, but are not in as wide a use.They all appear to be rated for stranded wire, as well as solid conductor wire. In fact, the big red ones i Have indicate stranded wire only if using 8 gauge...but not much of that on your average layout with the price of copper these days. It's the smaller wire nuts that are used most frequently. No, nothing with wire nuts small enough to wire your DCC loco, but really small enough for most practical uses under the layout. The small gray wire nut is rated at a minimum of 2 #22 gauge conductors up to a maximum of 2 #16 gauge conductors. So right there is a wire nut that can be used to connect your small drops from the rail up through the sizes commonly used for layout. Need to connect more wires? The yellow ones are rated from 2 #22 all the way up to 3 #12 wires. They really are a little big for just two wires of the #22 stuff, but cover just about every connection likely to be made with layout wiring. Sometimes when wiring a complex block with lots of feeders, you need something BIG. The red wire nuts can handle a pair of #8 of 2 or 3 #10 to as many as 6 #18 wires (or some combination in between). So there should be no concern that the wire nut isn't rated for for the wiring in layout use. Just guessing here, but I've likely got well past 2,000 connections under the layout. No way am I soldering that many wires over my head -- and I suspect they're just about as cheap as solder and electrical tape -- although once done a soldered connection is as good as it gets, although somewhat more permanent than a wire nut. |

|

|

|

Post by riogrande on Oct 16, 2014 5:10:01 GMT -8

Well, I never said wire nuts are a better connection, I didn't know you never said that - mainly because, as I said, I didn't have a clue as to what they were until you fed me with a spoon. My eyes glazed over at an unfamiliar term. The only clues I had really were from the choices in the poll, and frankly that "work of the devil" could have had the effect of biasing the reader - especially when they were neutral like me!  You seem like a very educated man so I'm guessing you are aware of the effects of bias in polls! Thanks for educating us about their use and the color codes etc. Personally since I'm a cheap guy, I'll probably not bother spending money (unnecessarily IMO) on them, and just keep using my roll of electrical tape! I don't see enough advantage on them to spend money on them! I'm that way with money! Quirky maybe! |

|

|

|

Post by Paul Cutler III on Oct 16, 2014 8:14:30 GMT -8

Electrical tape is even worse than wire nuts, IMHO. And shrink tubing is $1.15 for 4 feet of it at Digi-key. If you only use 1/2" per connection, that's 96 connections one can make for a buck fifteen...or 1.2 cents per. Shrink tubing will never fall off and never leave a gummy residue.

|

|

|

|

Post by riogrande on Oct 16, 2014 9:21:32 GMT -8

Well, maybe you can add electrical tape to the "hidden shame" list along with wire nuts!  |

|

|

|

Post by mlehman on Oct 16, 2014 10:03:24 GMT -8

Well, maybe you can add electrical tape to the "hidden shame" list along with wire nuts!  Oh yeah, that's something else I use, but mostly the liquid kind to insulate where I tap into the bus for power, where I prefer to solder despite the hazards....looks a lot like that ominous black oil in the X Files....heh, heh, heh.  |

|

rdrr

New Member

Posts: 1

|

Post by rdrr on Oct 19, 2014 15:57:03 GMT -8

Always wondered why no one mentions using wire nuts for wiring joints. I'm also an electrician who has used countless wire nuts over the past 40 years. Fast, foolproof, easily undone when needed when installed properly; whether they are inside a JB or not. As when used with line voltage wiring, solid or stranded, always twist wires first and then spin on wire nut firmly. If something ever happens to my layout to cause one of these joints to fail, I'll have much bigger problems than troubleshooting the wiring.

I won't post a pic from the underbelly of my benchwork, but I assure you I'm fussier than most with how it looks.

|

|

|

|

Post by mlehman on Oct 19, 2014 21:07:44 GMT -8

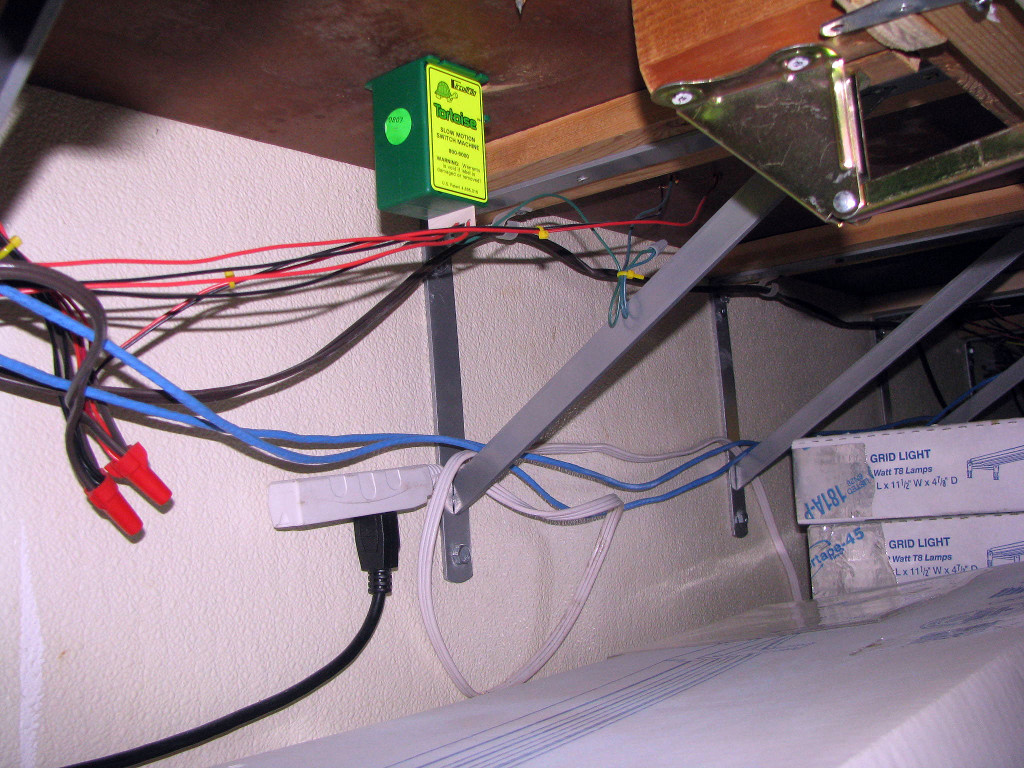

Welcome to the forum, rdrr! You're a courageous soul indeed to jump into one of our little dust-ups with both feet. It's really a great bunch, even though many of us do like to march around the town square with torches and brickbats from time to time.  And it's good to get another professional opinion on using wire nuts. I'm pretty much a barnyard electrician, learning most of what I know down on the farm when I was a kid and then around the house. I figure if you're scared of your layout being wired with 'em, you should start pitching a tent and sleeping in the backyard just to be sure the house doesn't catch fire because of their deficiencies... Just kidding... You did jog me to take a pic of a representative installation, because I thought of that earlier, then I...um...well, I forgot, I guess, don't remember...anyway, here's a pic to illustrate. Dang CRS...   This is under one end of staging, thus the atypical metal brackets. Other than that, it's got several aspects of how I repurpose elements of household wiring for model railroad use. Ignore the power/extension cord and blue ethernet cables as irrelevant here. On the left with the two red wire nuts is the drop from the bus. I use #16 brown lamp cord off a #12 THNN bus conductor for my drops, and they are soldered and swathed with liquid electrical tape at that connection. Here at the other end of the line is where the various drops from the rails and switch machines are attached for this area of the layout. The wires are grouped into red and black. You may see the colors reversed every once in awhile, as I'm a bit dyslexic, so don't always catch when that happens until I go to wire things up. I usually use my multimeter's continuity checker as I lay and wire track just to be on the safe side. It should be noted that the red wire nut can hold a bunch of smaller wires, although this number is usually not stated on the box. Use common sense and good wiring practice and you should be good. On the Tortoise, the outside wires, one red, one black, make up the control circuit. Reversing them throws the machine as most know already. The contacts may be a little more mysterious if you don't do hot frogs, but basically one is fed red/+, one is fed black/- and last one, the green one, to the frog, which is fed power from the red and black. Typically, these use the small gray wire nuts to attach them to longer wires if they don't reach the main power. They range from 18 to 22 gauge and usually in just red, black, green, plus the brown lamp cord. Then add some zip ties to neaten things up. A big part of using wire nuts successfully under the layout is managing wire length. Cut the wire to the optimal length, place things up high on the underside and zip tie the slack so the cable/bundle is neatened up. Next to the lower right corner of the Tortoise, screwed into the crossbeam above, is a white plastic J-hook. These are used for hanging Xmas lights and you can find them at the big boxes right now with the holiday lighting. Even if you don't use wire nuts, they are another dirt cheap item I've adopted. There are fancy ones; the best ones are just plain Js that you have to drill a hole in to attach them with. The wire bundle is simply hooked or put in its place, so is easy to also take back down. I have a few, but generally don't use the closed loop type cable holders as after you screw them in, you have to thread any wires going back through them. That's pretty much it, although this is a simplistic example. Much of the layout was originally two-cab DC through MRC CM20s, so everything was wired plenty heavy enough as original, I just wired into the bus of Cab 1 -- while the other bus sleeps.

|

|

|

|

Post by gmpullman on Oct 19, 2014 21:14:21 GMT -8

You can count me in as an avid wire nut user, too. Now there ARE places for barrier strips and fork terminals (I was fortunate enough to get a big stock of top quality T&B Sta-Kon terminals from a retired electrician!) and quite a bit of my old DC wiring was crimp terminals and barrier strips... BUT when I ripped out all my old DC block control and ran #12 THHN for my DCC buss I used wire nuts at nearly every connection right up to the 20 ga. feeders that are soldered to the rails.

Quite a few times I've had to do some trouble-shooting and I found it painless to twist off the wire nut and separate the wires for isolation OR frequently I've added additional "sub" feeders off the #12. Worst case scenario is I have to clip and re-strip the wire if it is too chewed up. With finer wire I make sure I strip back enough insulation so I can wrap the finer wire around the heavier wire before I twist on the nut. I light tug makes sure it has gripped the wire OK.

My buss doesn't follow the usual linear configuration most layouts seem to feature. I use more of a hub & spoke arrangement. The main feeder coming off the breaker runs to near the center of the power district (I have three boosters and 10 power districts plus three reversing sections) from there I twist maybe four or five #14 wires that radiate to areas where the feeders are mostly concentrated.

Sometimes I daisy-chain several #12s if I need more of a linear arrangement (none of my power districts run more than about ten feet of benchwork)

The main thing I try to manage is to use Ty-Raps (or zip-ties as some call them) and anchor my connections either using screw-eyes or nylon strain relief clips that screw to the benchwork. I also use dozens of the peel-n-stick squares that anchor the tie-wraps to the benchwork. In the beginning I left these loose until I ran almost all my wiring and then snugged them up but still left room to thread additional wires if needed.

Those little grey wire nuts (I get the Ideal brand) will work all the way down to a pair of #22 wires www.cableorganizer.com/cable-termination/ For small solid wire the "Insure" connectors are pretty quick and easy but they are not as flexible to remove or add wires to as the wire nuts.

Just my 2¢ Ed |

|

|

|

Post by mlehman on Oct 19, 2014 21:56:25 GMT -8

Hi Ed, Thanks for your excellent contribution. You can count me in as an avid wire nut user, too. Now there ARE places for barrier strips and fork terminals (I was fortunate enough to get a big stock of top quality T&B Sta-Kon terminals from a retired electrician!) and quite a bit of my old DC wiring was crimp terminals and barrier strips... I certainly agree. Use the right connector best suited to the job. Wire nuts are definitely not for every connection BUT when I ripped out all my old DC block control and ran #12 THHN for my DCC buss I used wire nuts at nearly every connection right up to the 20 ga. feeders that are soldered to the rails. [/p] [/quote] Yeah, great example where the wire nut is useless is where you attach to the rail. Rail nuts, anyone?  If my bus wasn't already in place, I could see doing wire nuts to it to. But it was just easier to hack it a bit to work with the DCC and it was good. All that soldering over my head in the first place is something others would probably desire to avoid. Quite a few times I've had to do some trouble-shooting and I found it painless to twist off the wire nut and separate the wires for isolation OR frequently I've added additional "sub" feeders off the #12. I mentioned the ease of making mods earlier, but it's important someone else note it again, because it IS so easy. I forgot all about trouble-shooting, thanks for bringing that very important aspect up. When wiring a block, I do it in bits, but I don't stop and test every connection -- you'd drive yourself nuts. I'll get some of the wiring complete, like a Tortoise install, or group of feeders, then check it with the continuity tester. If it shows continuity, i.e. bad, it's a short, then I start trouble shooting, Usually, it's a matter of swapping a wire, which is just so easy with this method. Worst case scenario is I have to clip and re-strip the wire if it is too chewed up. With finer wire I make sure I strip back enough insulation so I can wrap the finer wire around the heavier wire before I twist on the nut. I light tug makes sure it has gripped the wire OK. [/p] [/quote]SNIP Those folks still looking for the right combination of Scotchlock conductor sizes are eating their hearts out right now. Conductor size becomes totally fungible, doesn't really matter, so long as it goes into the wire nuts neatly. From big to small, the wire nut accommodates them all cheaply, quickly and easily. The main thing I try to manage is to use Ty-Raps (or zip-ties as some call them) and anchor my connections either using screw-eyes or nylon strain relief clips that screw to the benchwork. I also use dozens of the peel-n-stick squares that anchor the tie-wraps to the benchwork. In the beginning I left these loose until I ran almost all my wiring and then snugged them up but still left room to thread additional wires if needed. Yeah, a little different than what I do, but very similar. Check out the J-hooks, as they are so fast to install and use. I will caution you on those sticky squares. It's been some time back (couple of decades), but I tried some 3M ones that failed after a year or so when they dried out. They do have some amazing sticky stuff now, though. Personally, I wouldn't trust them, but it's because I got burned on them before I started using wire nuts. Those little grey wire nuts (I get the Ideal brand) will work all the way down to a pair of #22 wires www.cableorganizer.com/cable-termination/ For small solid wire the "Insure" connectors are pretty quick and easy but they are not as flexible to remove or add wires to as the wire nuts. Just my 2¢ Ed Yep, Ideal is generally what I use now. There are several good brands. I've also used GB Wire Gards (wing nuts) with success. Thanks again for adding your experience to the thread. |

|