|

|

Post by fishbelly on Dec 23, 2023 8:28:04 GMT -8

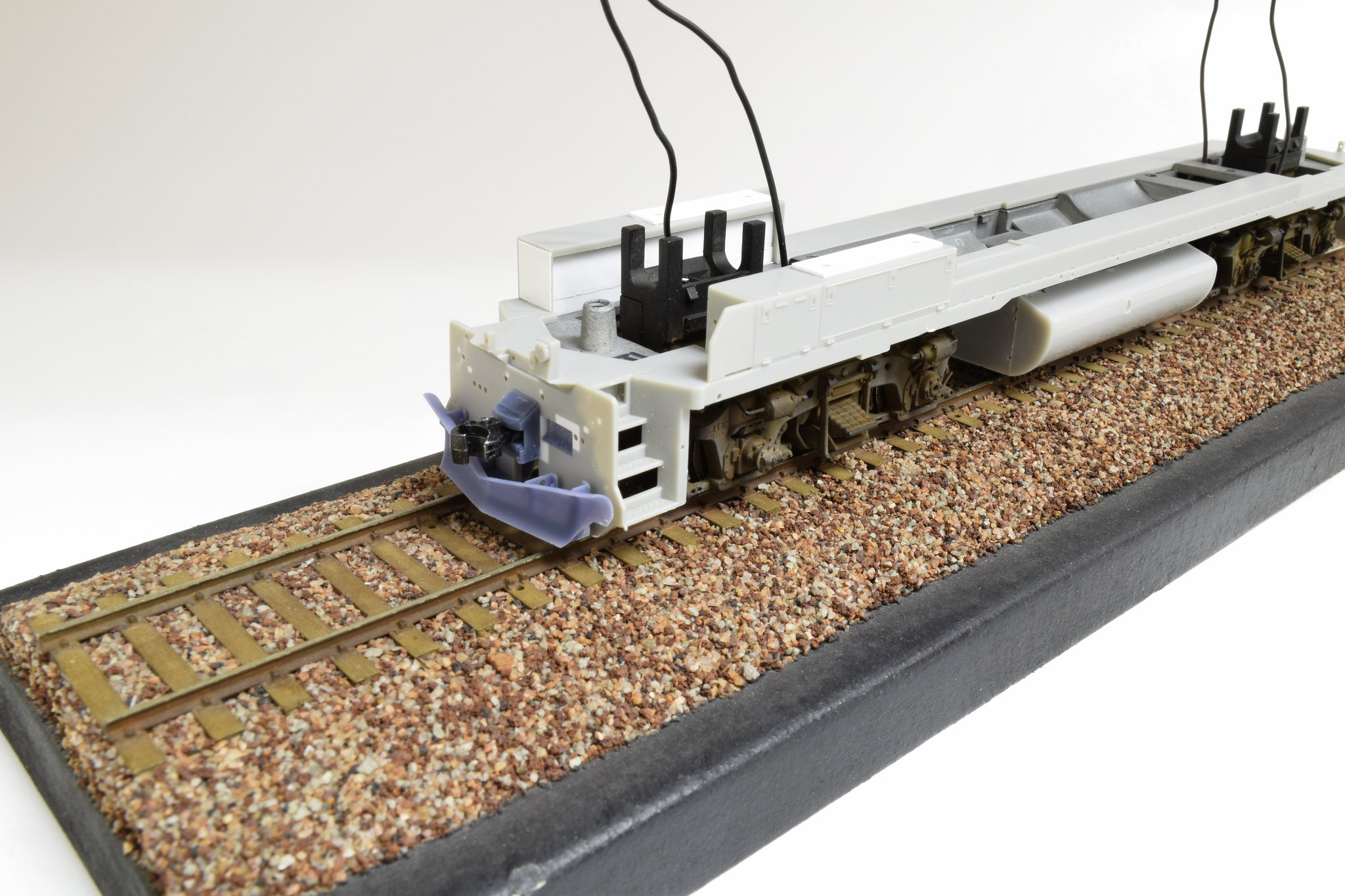

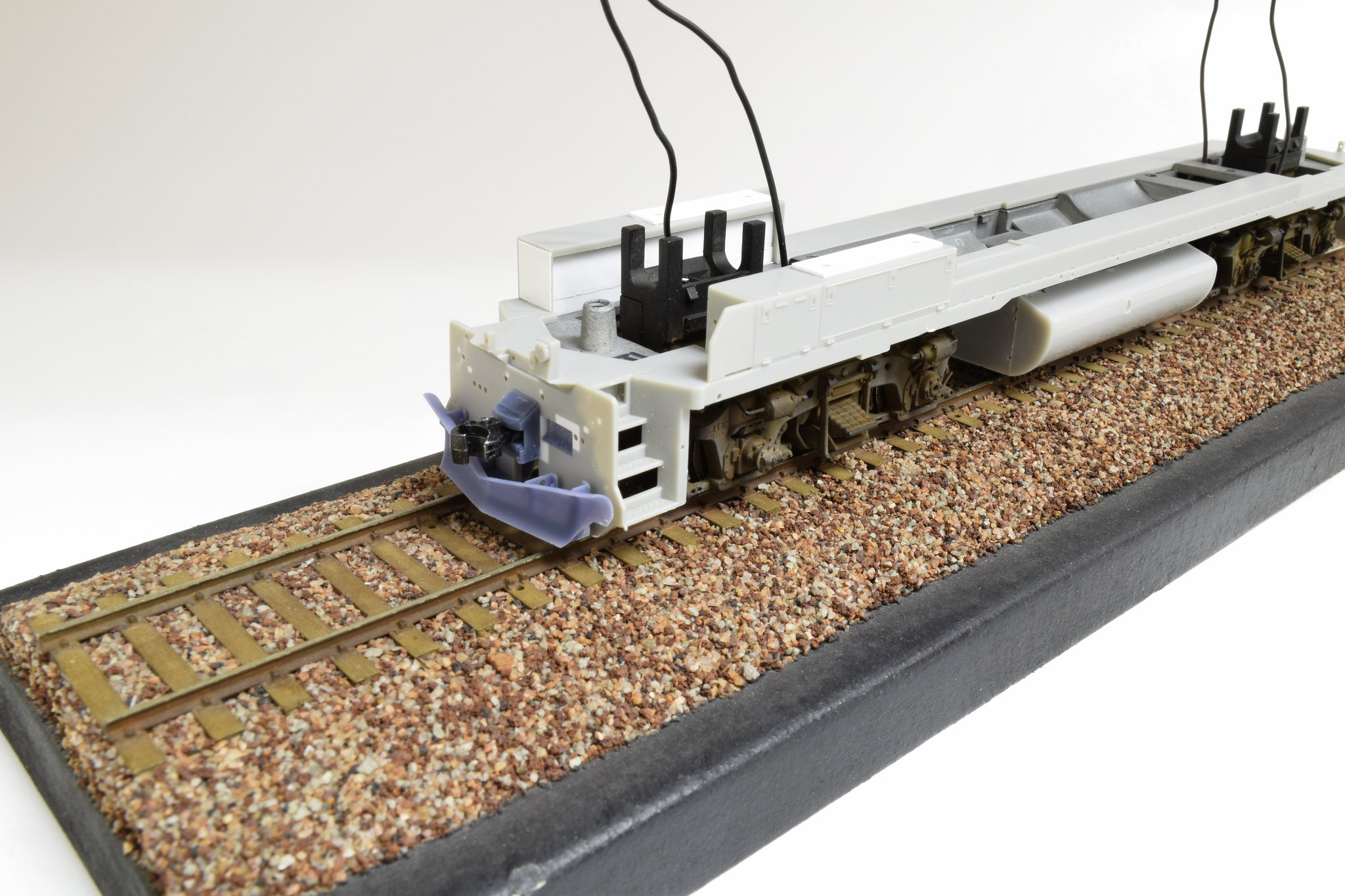

I have come back to modeling how I used to. Full on detail paint and weathering. The nostalgic stuff was fun, but I find it is time to get back to the RPM style of modeling I used to do. I have also picked up on my original proto-freelanced railroad. The Copper State Railway. I have written the history so that I can bring it back to the era I like modeling. Late 1960's. As with all my models I start from the bottom up. The trucks are done and I am currently working on the frame. When I can get decent photos taken of the trucks. I will post them in this thread. For now and my first post in this project. I am working on reconstructing the pilot plate. Or rather putting things in their rightful place. Here is a 3D assembly of the parts I have finished. Once I get the coupler all lined up and the components placed properly, I can then move on to designing the photo etch for the deck. There is a very good reason I am designing in this method. It has to do with the assembly process I am going to use. Before I can build the model, I need to design the parts and make sure they fit before I glue anything together. The joys of having a 3D printer are that you can design parts on the fly. No waiting for days or weeks for part designs to come in from a 2nd or 3rd party vender. I have been working on this Atlas GP38 and I want to really put some of my design ideas to the test. Some of the ideas work and some do not. I do not have to design the whole part at once. I can design the basics and when I am confident that it all fits. I can then add all the fine detail. What is also great about this and it depends on the resin you use. All the bolt heads come out very crisp and visible. Here you see the assembly of the parts I designed for the pilot plate except for the plow. The plow is from Donnell Wells. Donnell and I use the same 3D drawing program and he was very kind to send me the plow file. One part is not shown and that is the pilot plate MU recess. What you see here are six separate part designs. 1. Pilot plate template. This is used to place over the Atlas pilot plate and cut out all the necessary holes. 2. Buffer plate. 3. Coupler lift bar brackets. Very cool because these parts come out looking exactly like they do here. Bolt heads and everything. I just wish I could get them cast in brass. I may look into that. 4. Plow. 5. Draft gear box. 6. Draft gear box lid. My next task is to locate the pin for the coupler shank. I will be using a Kadee scale head medium length coupler. I have remove the whiskers and shave a bit off the width at the pin hole.

Brian |

|

|

|

Post by nsfantodd on Dec 23, 2023 9:07:36 GMT -8

Looks great!

Really love the draft gear detail behind the pilot plate!

|

|

|

|

Post by fishbelly on Dec 23, 2023 15:58:34 GMT -8

The design work is done for the draft gear box, draft gear box lid and buffer plate. Nothing is glued on yet. The coupler is dead on center with the Kadee coupler gauge. This is the front pilot of course. For the rear pilot I need to design the pilot beam at the bottom of the pilot plate with the MU hose boxes. Other items to note. The truck Brake Cylinders are my own design and 3D printed as well as the Speed Recorder. The fuel tank is from Athearn.

Brian |

|

|

|

Post by drolsen on Dec 23, 2023 18:11:30 GMT -8

Brian, that looks really fantastic. The buffer plate is really a game changer in terms of improving the appearance of a diesel model like this. I'm glad to see some manufacturers are finally addressing that, but they'll always be forced to compromise to some extent to make them Kadee compatible.

It hadn't really dawned on me that the pilot MU access plate has been shifted outward on EMD models all these years to accommodate the too-wide draft gear boxes. The way it's adjusted on yours really shows how much we've been compromising all this time.

I believe you mentioned in another post that you were considering whether to address the Atlas stepwells. Those have always bothered me, but I think for me it's the "sawtooth" look of the back side of the inboard wall of the stepwell, behind the steps, more than the depths of the steps themselves that they compromised to allow them to release from the mold. I've always wondering if a quick fix could be to make a corresponding "sawtooth" piece that fit against the back of the stepwell to fill it in and create the proper angled back edge. The issue would be how to bled it all in without completely removing the steps, puttying, etc.

Looking forward to the rest of your project!

Dave

|

|

|

|

Post by fishbelly on Dec 23, 2023 19:53:18 GMT -8

Thank you Dave. I appreciate the comments. I got all my pilot plate dimensions off an ex Penn Central GP38 here in town. Modeling is all about a series of compromises. Which ones we can live with and which ones we cannot. There are some minor compromises on the pilot plate to make it all work. They are not noticeable though.

I think what I am going to do with the step well is to fix the depth of the inner plate and put photo etched steps in. They will belike the Cannon & Co. Atlas step sets where they have the pilot plate notch. I have done these steps in the past, but I need to update my artwork to include the representations of the little pimple nubs around the holes.

I just finished the drawing for the rear MU pocket pilot beam. I will test print it tomorrow and see what the best orientation is for printing. Once I get that dialed in. Then it is time to design the tread plate and step sets and any other photo etch I can think of for this model. Waiting for the photo etch is going to be a bit of a setback on progress. I am sure I can work on other parts of this model in the meantime. Probably the inner step well plate.

Brian

|

|

|

|

Post by fishbelly on Dec 25, 2023 9:49:17 GMT -8

Merry Christmas to everyone! I really do hope your day is fantastic and full of family and cheer. I have finished the 3D design and printing of the pilot plate parts. The Atlas pilot footboard beam was just way to small. I used what information I have on the prototype pilot beam and designed a new on. The photo etch is from my stash of etchings I have done over the years. I still need to add the pilot beam bolt plate. It will be done in photo etch. If you look very closely. You can see I have added the wire bead around the MU hose pocket. Nothing is glued in place yet. That will happen AFTER I install the tread plate and steps. With all this 3D design work done on the pilots. I can now turn my attention to the photo etch design work. I need steps, tread plate and some pilot plate pieces. Probably some other stuff I have not thought of as well.

Brian |

|

|

|

Post by 12bridge on Dec 25, 2023 10:58:58 GMT -8

Brian, that looks really fantastic. The buffer plate is really a game changer in terms of improving the appearance of a diesel model like this. I'm glad to see some manufacturers are finally addressing that, but they'll always be forced to compromise to some extent to make them Kadee compatible. It hadn't really dawned on me that the pilot MU access plate has been shifted outward on EMD models all these years to accommodate the too-wide draft gear boxes. The way it's adjusted on yours really shows how much we've been compromising all this time. I believe you mentioned in another post that you were considering whether to address the Atlas stepwells. Those have always bothered me, but I think for me it's the "sawtooth" look of the back side of the inboard wall of the stepwell, behind the steps, more than the depths of the steps themselves that they compromised to allow them to release from the mold. I've always wondering if a quick fix could be to make a corresponding "sawtooth" piece that fit against the back of the stepwell to fill it in and create the proper angled back edge. The issue would be how to bled it all in without completely removing the steps, puttying, etc. Looking forward to the rest of your project! Dave Scale buffer plates is a huge pet peeve of mine lately from the mfg's (some are better then others). What's the point of all these scale details when you have a 4' wide hole in the pilot. I have a number of them I plan to do for my parts line, its just finding the time to do them all. I have the SD7/9 one just about done, and am planning the SW style next. Its another part that there is just so many variations of, especially on EMD's. I have two Alco ones measured up as well. |

|

|

|

Post by Donnell Wells on Dec 25, 2023 13:47:49 GMT -8

Brian, that buffer and pilot beam look awesome! Whenever I start modeling again, this is exactly where I'm going to take things! We will likely never get exactly what we want the way we want it from manufacturers given the constraints of mass production, and that's okay because they do provide some really "good bones" to create excellent models! I have a ton of old blue box stuff that is itching to be upgraded!

Donnell

|

|

|

|

Post by csxt8400 on Dec 25, 2023 20:44:34 GMT -8

This is really fantastic stuff, Brian.

|

|

|

|

Post by Colin 't Hart on Dec 26, 2023 0:10:03 GMT -8

Merry Christmas to everyone! I really do hope your day is fantastic and full of family and cheer. I have finished the 3D design and printing of the pilot plate parts. The Atlas pilot footboard beam was just way to small. I used what information I have on the prototype pilot beam and designed a new on. The photo etch is from my stash of etchings I have done over the years. I still need to add the pilot beam bolt plate. It will be done in photo etch. If you look very closely. You can see I have added the wire bead around the MU hose pocket. Nothing is glued in place yet. That will happen AFTER I install the tread plate and steps. With all this 3D design work done on the pilots. I can now turn my attention to the photo etch design work. I need steps, tread plate and some pilot plate pieces. Probably some other stuff I have not thought of as well.

Brian Great looking modelling. Could you photograph this side-on? I'm curious about the clearance -- from the angle in the photo above the footplates on two units MUed would hit each other. |

|

|

|

Post by fishbelly on Dec 26, 2023 8:52:28 GMT -8

Showing the coupler alignment. Pay no attention to the gap at the top of the buffer plate. Nothing is glued in place so it is hanging loosely in position. The coupler on the GP35 to the right has been repositioned inboard a bit as well.

Brian |

|

|

|

Post by kentuckysouthernrwy on Dec 26, 2023 12:31:01 GMT -8

You’re doing nice work Brian. Well above my patience level and my standards are less stringent. Persist…

|

|

|

|

Post by fishbelly on Dec 29, 2023 18:46:42 GMT -8

Tonight I sent off the etching artwork for the treadplate and steps along with a few other items.

I noticed one thing today. A few weeks ago I had 3D printed some new 48" radiator fan housings. I posted a thread about it. After time has passed the resin shrinks a little. Not much, but just enough to not allow the Cannon fan grill etchings to fit in. It shrunk in diameter about 0.001" to 0.0015". I did a test and upsized the file by 1.006%. I want to see if that will now shrink to the correct size. I suspect it will.

Once the etchings are delivered. I will be able to go to town on this model and really start the build work. The design time is always a rough time for me when working on the project. I do not see any progress on the model so it is discouraging and I get bored and I cannot work on anything until the etchings come in. I made it through without stopping and hopefully the payoff will be big.

Brian

|

|

|

|

Post by markfj on Dec 30, 2023 7:32:25 GMT -8

Brian, I still have the set of steps you did years ago for the Atlas GP38/40. Did you make significant changes to this design? (Pardon the crappy photos.)   Thanks, Mark |

|

|

|

Post by fishbelly on Dec 30, 2023 8:32:19 GMT -8

No, I used that very design and added it to my tread plate set.

Brian

|

|

|

|

Post by fishbelly on Dec 31, 2023 12:40:07 GMT -8

Wishing you all a Happy New Year! Not really being able to do anything substantial to the model. I thought I would give it a try and design the crossbar or whatever you would call it that attaches both sides of the Blomberg side frames at each end. I do not have any dimensional information. Only photos so I scaled and estimated what I thought might be correct and came up with this design. I think it all worked out well. Not really visible on the model. Although in front of and behind the fuel tank it is so it helps to fill in that bit of detail. I do not need to glue them in place, although I think I will use some tacky glue on final assembly. Now I just need to paint and weather them to match the side frames.

Brian |

|

|

|

Post by 12bridge on Dec 31, 2023 12:57:40 GMT -8

Nice. That really fills in the gap. Never seen a hollow one on top like that. Wonder if it was a later design change.  |

|

|

|

Post by big train james on Dec 31, 2023 13:27:58 GMT -8

I've seen the end part of the trucks referred as a "transom" in various places. It makes sense, so that's what I call it.

I was going to agree about never having seen one with the face open. I'm used to them having an opening facing toward the bolster. But then I took a look through my stash and the very first Blomberg photo has the open top. Learn something new everyday.

Jim

|

|

|

|

Post by fishbelly on Dec 31, 2023 13:40:34 GMT -8

Not a great photo. I will get better ones when I am out there again. Seems I tend to miss important information when I am not concentrating on it. Here is an RJ Corman unit taken on one of my trips to their yard in downtown Fuquay Varina, NC. You can see the three casting holes on the top. Actually I just noticed. I think there are four. Also there is one at each end. Oh and this is a photo of a GP38-2. When the 38 is back in town again. I will make it a point to get the photos of it. And I do believe you are correct 12bridge. I just looked over my photos of the RJ Corman GP38, ex PC unit, and I found a photo that gives me a view of that area. No holes on top or on the ends. The GP38-2 is a casting from a different manufacturer possibly and has the holes. The 38-2 is an ex L&N unit. I will make the changes. Thanks for pointing that out so I can correct my mistake for this unit.

Brian |

|

|

|

Post by stevef45 on Dec 31, 2023 14:40:33 GMT -8

Wishing you all a Happy New Year! Not really being able to do anything substantial to the model. I thought I would give it a try and design the crossbar or whatever you would call it that attaches both sides of the Blomberg side frames at each end. I do not have any dimensional information. Only photos so I scaled and estimated what I thought might be correct and came up with this design. I think it all worked out well. Not really visible on the model. Although in front of and behind the fuel tank it is so it helps to fill in that bit of detail. I do not need to glue them in place, although I think I will use some tacky glue on final assembly. Now I just need to paint and weather them to match the side frames.

Brian You think these would fit athearn genesis blomberg trucks? |

|

|

|

Post by fishbelly on Dec 31, 2023 14:59:12 GMT -8

I have no idea if these would fit the Athearn Genesis frames. Currently they are on Athearn Blue Box frames with adapters to fit the Atlas gear towers.

Brian

|

|

|

|

Post by big train james on Dec 31, 2023 15:39:47 GMT -8

Nice. That really fills in the gap. Never seen a hollow one on top like that. Wonder if it was a later design change. I took another quick dig through some of the photos I have, and I've got examples of two trucks cast during the Rockwell era with openings on top. One has the old Rockwell Manufacturing logo, and the other has the Rockwell International logo. I also see examples of L.F.M. and GSC castings, both of which are closed on the top and open on the inboard face. The GSC casting is probably an outlier of sorts, I don't believe they did a lot of truck frame castings compared to L.F.M./Rockwell. It sounds like the change to the end transom configuration coincided roughly with the Rockwell ownership. And after all that, I looked at the Trainiax page on Blombergs, and he spells it all out. It's pretty much L.F.M. versus Rockwell, with GSC and Dafasco (forgot about them) having their own styles similar to the first two. trainiax.net/metruck-gp.phpJim |

|

|

|

Post by stevef45 on Dec 31, 2023 17:38:47 GMT -8

I have no idea if these would fit the Athearn Genesis frames. Currently they are on Athearn Blue Box frames with adapters to fit the Atlas gear towers. Brian would you sell a pair? I'd love to see if they work and if they do, maybe buy more. |

|

|

|

Post by fishbelly on Dec 31, 2023 17:55:47 GMT -8

I have no idea if these would fit the Athearn Genesis frames. Currently they are on Athearn Blue Box frames with adapters to fit the Atlas gear towers. Brian would you sell a pair? I'd love to see if they work and if they do, maybe buy more. Just send me $11.00 Friends and Family to paypal to cover the cost of shipping and I will send you a few sets. I took all the holes out though so they are solid. Paypal is brian_banna@yahoo.com I have to redesign them too. Thanks to a very good friend. I now have the dimensional information for them. He sent me a few EMD drawings tonight. I will redraw them tomorrow and can send them out to you in Tuesdays mail. Brian |

|

|

|

Post by fishbelly on Jan 4, 2024 10:59:49 GMT -8

Update:

I changed the title of the thread. This is going to be a Penn Central GP38. Early oil bath version. The urge to get more CPT&C and related stuff going was the reason for this. I will have to rebuild the trucks now. Strip the paint and add different journals. Also the plow will no longer be used and instead I will use footboards on the front.

Today I made payment for my photoetch order. I already received notice they are working on it so I should receive it in about a week or so.

In the meantime I will continue work on the three CPT&C GP35's I had going. I am about 70% of the way through these.

Brian

|

|

|

|

Post by ambluco on Jan 4, 2024 15:38:27 GMT -8

You do a lot of modeling. Would it be worthwhile just setting the trucks aside for another model and doing a new pair?

|

|

|

|

Post by fishbelly on Jan 4, 2024 15:56:29 GMT -8

You do a lot of modeling. Would it be worthwhile just setting the trucks aside for another model and doing a new pair? Changing the trucks over is a piece of cake. Take me a couple days and done. Brian |

|