|

|

Post by tony on Apr 25, 2024 20:42:21 GMT -8

Does anyone have experience with vacuum forming for models railroad cars to create those inserts to hold models?

I'm looking to make some custom multi-car packs. One of the use cases is Intermountain PFE R-40-23 cars. I have about 50 of these that were built from kits. I have been using A-Line boxes, but the vacuum formed inserts really do work well and I think is a superior approach than using foam and cardboard with the models resting on side details.

The multiple car inserts would into a cardboard box, but with 4 -5 layers - each layer having 6-7 cars.

I'd like to find a company that can do this type of work.

|

|

|

|

Post by Mr. Trainiac on Apr 25, 2024 21:25:14 GMT -8

Before vaccuforming, have you considered getting different boxes? I have some that can store cars upright. That way they rest on their wheels rather than the sides. Add some clear plastic sheets like most new models come wrapped in, you can lift the models out like a sling.

It's probaby cheaper than comissioning custom trays. The hardest part would be designing the insert bucks. If you have some RTR models of the same car, maybe you could make a negative mold of one of the trays. I've seen people make homemade vaccuform tables, and there are some hobby/light commercial grade machines available online too.

|

|

|

|

Post by edwardsutorik on Apr 26, 2024 5:19:55 GMT -8

Before vaccuforming, have you considered getting different boxes? I have some that can store cars upright. That way they rest on their wheels rather than the sides. That's exactly how the boxes he has work, at least for me and everyone else's I've peered at. Placing things on their sides in these A-Line boxes would be quite a challenge IF you use the included divider inserts (making four rows). The A-Line "system" is NOT designed to hold rolling stock on its side. That's like what I do for my A-Line boxes. A-Line sells sheets of thin white foam that does the job nicely (you cut to fit). I have MANY boxes stacked up that are packed that way. Haven't yet had a problem, and I occasionally drive them to Free-mo set-ups. I also use their grey foam blocks between cars and locos (in an individual row), and I don't use the grey foam strips that come with the boxes. Ed |

|

|

|

Post by packer on Apr 26, 2024 5:49:33 GMT -8

I've not tried vacuum forming. I use some 1/8"(?) foam to make an offset and glue them to the inside of the box to clear any details. Then I glue a pice of carboard to a pice of foam to go against the wheels. Then some foam for the top and ends of the car, again avoiding any details. I'll finish them off with plastic wrap for the car. Haven't had any issues. Most of my IM kit cars have no roofwalks (Covered hoppers just get one in the middle), I'd imagine this'd be trickier if one has them.

|

|

|

|

Post by Baikal on Apr 26, 2024 6:51:27 GMT -8

That's like what I do for my A-Line boxes. A-Line sells sheets of thin white foam that does the job nicely (you cut to fit). I have MANY boxes stacked up that are packed that way. Haven't yet had a problem, and I occasionally drive them to Free-mo set-ups. I also use their grey foam blocks between cars and locos (in an individual row), and I don't use the grey foam strips that come with the boxes. Ed

I use either velour fabric or "car headliner" fabric which has a thin foam backing. Both available from big fabric stores, cheap.

I cut 1/2" thick or so foam into pieces to keep models from shifting/rolling. Tho they don't move much sitting on the thin foam.

For boxes I use the Plano 3730 boxes or equivalant. Models stand upright.

|

|

|

|

Post by trainboyy on May 1, 2024 3:27:53 GMT -8

On the topic of A-Line boxes, is there any reason why they cost so much? They're just big cardboard boxes that you have to assemble yourself; I bet U-Line makes the same size box and you can buy it for one tenth the price.

|

|

|

|

Post by jonklein611 on May 1, 2024 5:25:25 GMT -8

|

|

|

|

Post by tony on May 1, 2024 7:56:03 GMT -8

I'd like to see a video of the patterns used for making a HO two piece vacuum formed packaging. Scaletrains said they were going to create videos of the model train making business. I saw they did one on EDM work, but haven't see others for that series. This one would be useful.

|

|

|

|

Post by slowfreight on May 1, 2024 8:52:19 GMT -8

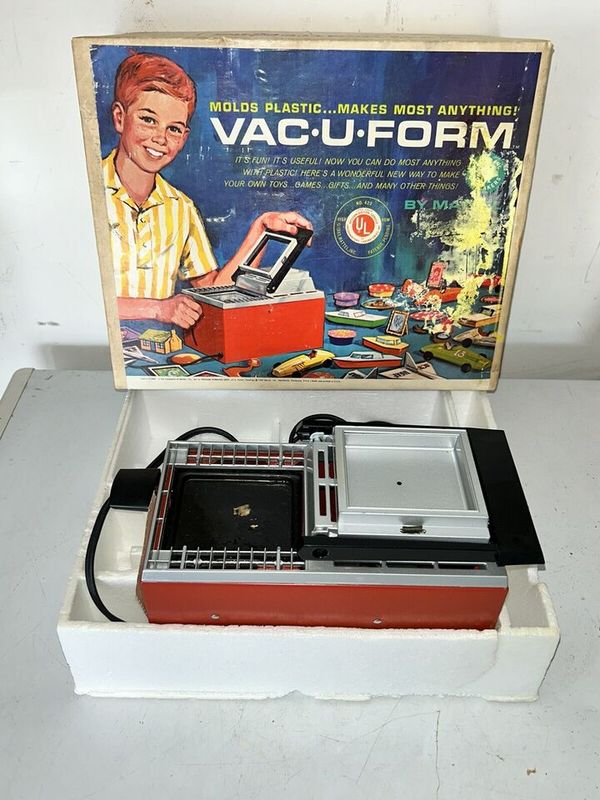

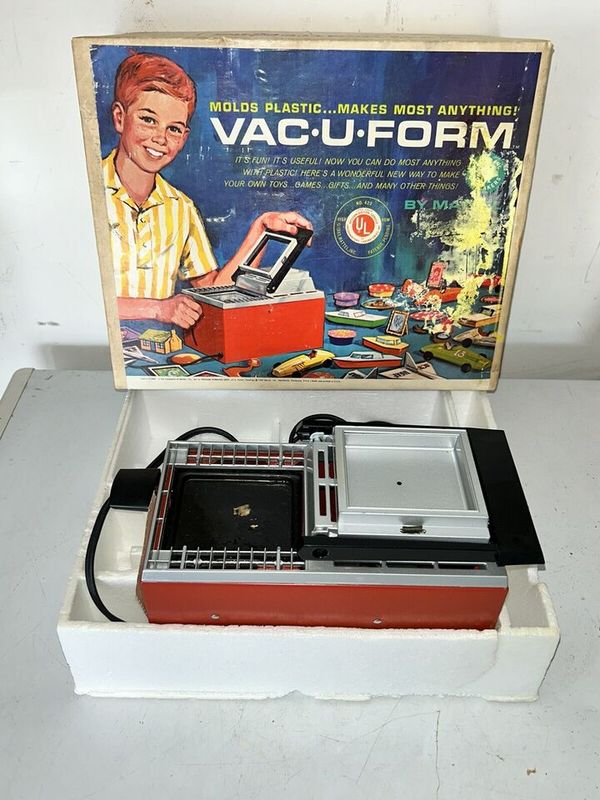

The vacuuform question makes me think of this:  A billion years ago, we used one of these at the hobby shop to repair a Noma talking station. They were the only thing Noma ever made for tinplate trains. The station had a mini record player and simple speaker inside and would call out the stops for the Broadway Limited. We had one where the little plastic speaker cone had disintegrated, and we made a pattern out of styrene and successfully formed a new cone using the Mattel toy in question. It'd never work for the original request in the thread, but fun anyway. |

|

|

|

Post by Baikal on May 1, 2024 16:08:18 GMT -8

On the topic of A-Line boxes, is there any reason why they cost so much? They're just big cardboard boxes that you have to assemble yourself; I bet U-Line makes the same size box and you can buy it for one tenth the price.

Selling price is determined by buyers (demand), not by inputs like material, labor etc.

They cost what they do because people are willing to pay.

Like when you sell your house, the price is determined by how much someone will pay (and they look at comps), not how much money you have put into the house.

|

|

|

|

Post by Baikal on May 1, 2024 16:25:18 GMT -8

The vacuuform question makes me think of this:  A billion years ago, we used one of these at the hobby shop to repair a Noma talking station. They were the only thing Noma ever made for tinplate trains. The station had a mini record player and simple speaker inside and would call out the stops for the Broadway Limited. We had one where the little plastic speaker cone had disintegrated, and we made a pattern out of styrene and successfully formed a new cone using the Mattel toy in question. It'd never work for the original request in the thread, but fun anyway.

Could never sell those today, lawsuits a-plenty.

Even as a kid I thought it had real model-making potential. 390 degrees yeah I got burnt. Did not sue.

|

|

|

|

Post by edwardsutorik on May 1, 2024 17:19:55 GMT -8

Selling price is determined by buyers (demand), not by inputs like material, labor etc. They cost what they do because people are willing to pay. Like when you sell your house, the price is determined by how much someone will pay (and they look at comps), not how much money you have put into the house.

I will suggest that inputs of material and labor are involved with setting the price. In particular, if the selling price is not higher than the production price, it makes little sense to produce the item, unless one is a charity. I do agree that demand is an element: if no one wants to buy your product, the price is irrelevant. If there IS demand, then there can be a "negotiation" over the price. I am sure that A-Line does not manufacture the boxes. They purchase them, in quantity. I don't know how much they pay. If anyone here really cared, they could likely get a quote from a maker. After the box is purchased and delivered, there are added costs like storage, packing, and shipping. And profit. And profit for "middlemen"--Walthers wants a cut, you know. It would be interesting to have a break down of the cost for these boxes. Oh, yes: quality. That's something that one usually pays extra for. I'll note that I can stack these boxes 18 high, without a problem. They are extremely sturdy. One way I've saved a good bit of money is by buying good quality pizza boxes to hold my trailers and containers. They don't need the "fancy" boxes. I just lay them out flat. About a buck a box, I think. A lot less than the A-Line. ONE reason for that is the incredible quantity of pizza boxes that are produced, compared to the A-Line boxes. And they're lighter duty and easier to make. They are NOT as strong as the A-Line, but "it works for me" (they'll stack at least 12 high). Ed |

|

|

|

Post by Baikal on May 1, 2024 17:28:20 GMT -8

Selling price is determined by buyers (demand), not by inputs like material, labor etc. They cost what they do because people are willing to pay. Like when you sell your house, the price is determined by how much someone will pay (and they look at comps), not how much money you have put into the house.

I will suggest that inputs of material and labor are involved with setting the price. In particular, if the selling price is not higher than the production price, it makes little sense to produce the item, unless one is a charity. Ed

Yep.

|

|

|

|

Post by edwardsutorik on May 21, 2024 11:38:18 GMT -8

This Adam Savage video on the subject just showed up on Youtube: I have not watched it, as I have little interest in doing this thing. Others may. Ed |

|

|

|

Post by grahamline on May 21, 2024 14:15:04 GMT -8

Between the ages of 12 and 22, my son provided me with a large supply of shoeboxes....

|

|