|

|

Post by jaygee on Oct 19, 2015 12:37:57 GMT -8

Well I do, and just discovered that the die cast frame has bought the farm! She's locked up tight as a drum. Too bad, this was a good looking loco...purchased back in 2002. I'm guessing that there will be little if any support for this thing over here. Oh well, just another reason to throw steam under the bus !

|

|

|

|

Post by atsfan on Oct 19, 2015 12:40:01 GMT -8

The frame locked up?

Or the drive train?

Usually a frame is a static piece of metal.

|

|

|

|

Post by jaygee on Oct 19, 2015 12:44:57 GMT -8

Die cast frame rot is the reason. The critical dimensions are now Chinese toast. It might be possible to make a dummy unit out of it, but probably not, as it will never roll right again.

|

|

|

|

Post by calzephyr on Oct 19, 2015 12:52:17 GMT -8

Remember, it a Bachmann. I saw one at a LHS back during that period and it did look nice overall. You can always display it if you like the model.

Larry

|

|

|

|

Post by mlehman on Oct 19, 2015 12:56:05 GMT -8

This is the sort of thing where ebay might turn up a basket case cheap enough. So long as the frame is good at this point, it'll likely stay that way. Usually a case of contaminated metal and probably all too common, so if everyone else is facing similar issues, this may not work.

And there are those who import Chinese models. It's entirely possible they may have a current offering that uses basically the same frame. Problem is that a frame is generally not considered as a R&R part. If it's bad, you need a new loco one way or another, but you might be able to part out the rest if you did need to go this route.

|

|

|

|

Post by Spikre on Oct 19, 2015 13:02:53 GMT -8

jaygee, don't throw Steam under the bus,throw Bachman under the Bus !! or tie them to tracks in front of a Talgo. am really glad that the Susie Q mike and Russian Decapod were passed on awhile back. Spikre

|

|

|

|

Post by theengineshed on Oct 19, 2015 13:33:53 GMT -8

And there are those who import Chinese models. It's entirely possible they may have a current offering that uses basically the same frame. Problem is that a frame is generally not considered as a R&R part. If it's bad, you need a new loco one way or another, but you might be able to part out the rest if you did need to go this route. Hornby in the UK had a bad run of Class 31s around 2002 too, Bachmann has had some British steamers with this problem as well. Hornby to their credit are still offering Hornby store credits if you return the locos, this is more than ten years after the fact. I have a Class 31 with the "mazak rot", can't be bothered to return it, postage to the UK, etc. Hornby and Bachmann both were offering replacement frames in the UK to those individuals who had the bad locos. In Hornby's case, when they produced a new run of Class 31s they ordered extra frames to cover the individuals that needed them. I'm surprised this hasn't cropped up here more, the manufacturers are all using the same factories. You can bet that if your Chinese QJ has this problem, others do too! |

|

|

|

Post by theengineshed on Oct 19, 2015 13:50:11 GMT -8

There was a recall! Trouble with mazak rot is that depending on the amount of impurities, it may take many years for the problem to show, typically the metal swells and goes crumbly. Needless to say, I'd avoid any models from the first run, regardless of condition. If Bachmann USA imported these, I'd contact them. Let them know that Bachmann UK covers this sort of issue. You might get a frame from a newer run of QJs... "The QJ's were Bachmann China's first steam locomotives, the first production run released in September 2001. A fault was present in approximately 100 of these models in relation to the alloy used in the chassis which would overheat and cause the whole engine to sieze up after a very short time. In 2009 a recall was issued and lasted approximately one month where owners were able to send their locomotive back for a complete replacement. I'm unaware if these replacement models featured the same original performance fault, as described below, or were the improved type from the fourth series." Chinese QJ Issues |

|

|

|

Post by roadkill on Oct 19, 2015 15:29:34 GMT -8

Not to be pedantic but it's "zamac", not "mazak". I've heard that some of the Overland Models Ajin-made Railpower replacement drives have shown zamak disintegration too, and those were made in S. Korea. Funny thing is, Bachmann has a history of this  . The 8 wheel drive U36Bs, F9s and GP40s from the early to mid Seventies were notorious for zamac rot, they would swell up to the point that not only wouldn't the shells come off, but the shells would split  !!! |

|

|

|

Post by mlehman on Oct 19, 2015 17:11:30 GMT -8

Not to be pedantic but it's "zamac", not "mazak". SNIP Pedantic or not, you're forgetting that the US and UK share a language that also divides them. Sometimes it really is Mazak, dependning on which side of the Big Pond you're on: en.wikipedia.org/wiki/Zamak |

|

|

|

Post by theengineshed on Oct 19, 2015 17:50:10 GMT -8

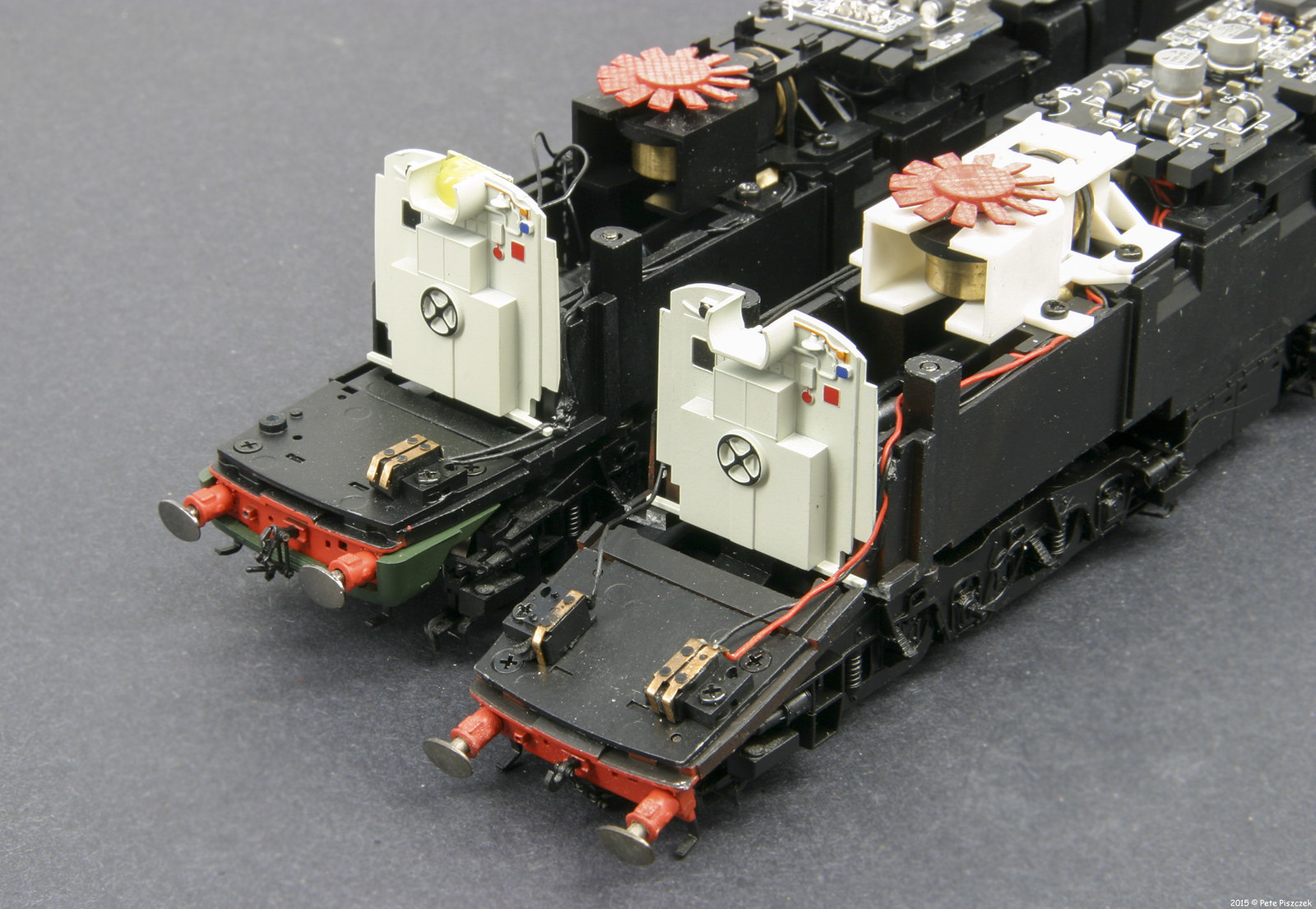

Zamak and Mazak zinc die casting alloys are basically the United States versus European names for the same alloys. Zamak was patented back in 1929 and used a reflux process to purify the zinc component of the alloy. The British later used an electrolytic process to purify the zinc, it was called Mazak. There are different alloy compositions that have their own trade names.  I'm just glad this has only happened to one locomotive I own, because it really is a bad situation. Here's a couple of photos of my Mazak nightmare. As the Mazak deteriorates, it swells, and the frame lengthens. This puts pressure on the plastic shell cracking it. The broken parts of the chassis were the thinnest parts, and had already cracked before I separated the chassis from the shell. Both ends of the Hornby Class 31 did this, and virtually the entire run of models had this problem. I took these photos back in 2009, might see if I can find it to determine how much more of the chassis has deteriorated.  Class 31 Hornby Metal Rot Class 31 Hornby Metal Rot by Pete Piszczek, on Flickr  Class 31 Hornby Metal Rot Class 31 Hornby Metal Rot by Pete Piszczek, on Flickr |

|

|

|

Post by bdhicks on Oct 19, 2015 20:13:06 GMT -8

I picked up one in the hopes of modeling one of the IAIS steamers, and the frame was cracked and it wouldn't run. Then I managed to find another one and it had the same problem. I dug out the calipers and the metal had not only gone brittle but also expanded. I had hoped maybe I could get something 3d printed, but I don't really know how to do 3d modeling and Shapeways metal printing is weird and doesn't seem like it would work for precision parts. I think there was only the one run of them for the US, but I saw that there was a run for China about a year ago so maybe you could track down one of those, from what I understand that sorted out some of the issues, but I have no idea if they got a better frame casting. This website has a lot of info on the Chinese market runs: www.chinesemodeltrains.com/encyclopedia_qj.html |

|

|

|

Post by theengineshed on Oct 19, 2015 20:18:57 GMT -8

A word of advice, disassemble the locomotive, that expansion exerts considerable pressure on the rest of the locomotive. The decomposing frame might deform the parts that are attached to it.

|

|

|

|

Post by WP 257 on Oct 20, 2015 4:13:57 GMT -8

Are there issues with more recent Chinese produced Bachmann steamers, like the 2-8-0's, having "zinc pest" as this is sometimes known???

Also, I was told that zamac is supposed to be a zinc aluminum alloy, not containing any lead whatsoever. The problem is lead impurities in the zamac causing the intergranular corrosion. There are other models out there made from zamac, like for instance the Oriental Limited/Powerhouse USRA 2-8-8-2's of the early to middle 1980's, where the entire boiler is zamac. I've never heard of one of those models having issues with intergranular corrosion, as of yet, but then if you keep the metal painted, which protects it from oxidation, it takes many years longer for issues to occur.

I heard a lot about this from Bowser many years ago. We made (they may still offer) replacement zinc wheels (with a pressed on plated tire) for the old Lionel pre-war trains, particularly the standard gauge trains from roughly WW I vintage. Those had severe issues with the zinc pest such that the wheels would eventually be so brittle that you could crumble them to dust in your bare hands. Lew English always said the best thing for collectors to do was to keep paint on older toys as it dramatically slows the corrosion process by sealing the metal from the air.

Some of Bachmann's frames are not painted, but are chemically blackened instead, making any impure zinc or zamac an exposed easy target to the oxidation process.

John

|

|

|

|

Post by jaygee on Oct 20, 2015 8:02:21 GMT -8

I had a Lionel UP Turbine tender from 2001 go bad after about 11 - 12 years. There was NO support of any kind with this junk, so now I'm VERY selective about what I get from Lionel. It better be something where I know I'll be able to get spare parts...like an EMD F3 frame.

|

|

|

|

Post by mlehman on Oct 20, 2015 8:20:39 GMT -8

Are there issues with more recent Chinese produced Bachmann steamers, like the 2-8-0's, having "zinc pest" as this is sometimes known??? Also, I was told that zamac is supposed to be a zinc aluminum alloy, not containing any lead whatsoever. The problem is lead impurities in the zamac causing the intergranular corrosion... John, I've not heard much in the way of people having issues with it lately. I suspect Bachmann/Kader cracked down on their suppliers and tests at least periodically to make sure they're getting good raw materials. Gotta consider that the Chinese have issues with contaminated baby formula, so what's a little lead in your soft metal?  In any case, it's the sort of issue that crops up from time to time. From what I've read over the years, it is both a known problem and one that even the best mfgs have had issues with at times. It does pay to inspect your collection from time to time of any items made with the stuff, but the alternative is brass in most cases...and that's not cheap as we know. |

|

|

|

Post by calzephyr on Oct 20, 2015 10:11:33 GMT -8

They also had problems with their drywall material for homes. Yes, let the buyer beware.

We tend to trust products from most companies until proven different. I purchase models thinking that a decent amount of quality is built in the product so their reputation will provide repeat sales and more sales in the future.

Some of the older brass used zamac frames and trailing trucks on steam models. Some of the early AHM and early Gem models used zamac parts to reduce costs. They would deteriorate and start falling apart after twenty or so years. Avoid any models with this type of material. Still, it is hard to determine the material if they are painted. Painting probably does extend the life of zamac.

The situation with the QJ 2-10-2 model is very deceiving. I looked at those when they were new in a shop and passed on the model, but they were detailed extremely nice for a plastic model at that time. I never once suspected any possible problem with the materials being used in that model.

Larry

|

|

|

|

Post by theengineshed on Oct 20, 2015 13:21:18 GMT -8

Also, I was told that zamac is supposed to be a zinc aluminum alloy, not containing any lead whatsoever. The problem is lead impurities in the zamac causing the intergranular corrosion. There are other models out there made from zamac, like for instance the Oriental Limited/Powerhouse USRA 2-8-8-2's of the early to middle 1980's, where the entire boiler is zamac. I've never heard of one of those models having issues with intergranular corrosion, as of yet, but then if you keep the metal painted, which protects it from oxidation, it takes many years longer for issues to occur. Does oxidation really play a role? Once the alloy is contaminated I don't believe that the alloy being painted or not makes much difference. The QJ first run, the Hornby Class 31, some Heljan locos, and the Bachmann UK stuff I have heard about were all manufactured around the 2000-2004 time frame, so as someone stated, I bet the manufacturers have really clamped down on quality control. That said, the OP had a fine running QJ till recently, so it took a decade or more for the problem to show with that particular frame. |

|

|

|

Post by WP 257 on Oct 20, 2015 13:47:35 GMT -8

Lew English Sr. was a Chemical Engineer who happened to end up making trains. He had a collection of pre-WWII Lionel trains whose insurance value was 1 million (so actual value may have been higher). He had extensive experience with repairing the pre-WWII Lionel trains (that was what he did day after day for more than 60 years, in addition to running his train manufacturing companies) and was well aware of the problem. He said keeping the metal painted retarded the corrosion process but would not stop it completely, so I have to believe him.

From my other hobbies, I know that all metals develop micro-cracks as they age. Normally this is not much of a problem, but the intergranular corrosion process which causes what we know to be "zinc pest" is apparently influenced by oxidation, and the micro-fractures are much worse. If you coat the metal with paint on both sides, it slows the process down.

The problem is not toys and trains made of zamac but only lead-contaminated zamac. Unfortunately we can't tell which is which till it's too late.

At various points, people have used lead in the zamac or other alloy processes because it makes the molten metal flow better into the molds, giving you greater detail and very nice finished castings. Unfortunately, the lead is the enemy in zamac. Bowser was very anal about keeping any bad lead castings that were going to be re-melted separate from the zinc, to avoid this problem. Bowser had some trains that were lead or pewter, and others that were all zinc and tin. It depended upon when the dies were made, as you could not interchange the dies to cast different types of metals.

I would suppose that from time to time we will still see bad metal trains and other toys coming out of China. They do what they can to slash costs, and sometimes cut corners, period. I'll not editorialize further.

Don't eat the paint on the brass models either, as the good factory paint jobs so prized by collectors very likely do contain lead.

John

|

|

|

|

Post by edwardsutorik on Oct 20, 2015 13:58:32 GMT -8

Ah, zinc pest.

I lost a cute little Rivarossi Dockside to that: The cylinders went, and perhaps the frame--it's been awhile. I bought it about 1963. I went looking for it around 1983, and it was terminal. It was the only Dockside that came with valve gear. And a pretty pathetic motor.

I've also got a bunch of old Ulrich kits tucked away. I think upwards of half have zinc pest. It's been a long time since I peeked. I'm kinda surprised, 'cause Ulrich was kinda the A team in die cast freight cars. Their operating triple hopper was my fave.

I've only got a couple of MDC metal cars. It's my impression that they didn't get the disease. Same for my smattering of MEW. But it's been awhile since I looked.

And, oh yes, jaygee inspired me to dig out my Lionel Turbine. OK, so far. And I finally put it on the DCC track. Sorta neat, sorta crude. Weighs a LOT!

|

|

|

|

Post by jaygee on Oct 20, 2015 14:09:50 GMT -8

Talked to the Bachmann techie today. The chooch is trash! I'll need to send it back to Bachmann for an exchange. Perhaps a pair of 45 tonners might do it ! I remember a lot of Hobbytown of Boston Alcos that came unglued after a few years. Amazing that Lionel had so few issues with this during the post war era.

|

|

|

|

Post by theengineshed on Oct 20, 2015 14:21:34 GMT -8

Talked to the Bachmann techie today. The chooch is trash! I'll need to send it back to Bachmann for an exchange. Perhaps a pair of 45 tonners might do it ! I remember a lot of Hobbytown of Boston Alcos that came unglued after a few years. Amazing that Lionel had so few issues with this during the post war era. Sorry you are going to lose your QJ but it is great that Bachmann is going to exchange it! |

|

|

|

Post by theengineshed on Oct 20, 2015 14:27:41 GMT -8

Lew English Sr. was a Chemical Engineer who happened to end up making trains. He had a collection of pre-WWII Lionel trains whose insurance value was 1 million (so actual value may have been higher). He had extensive experience with repairing the pre-WWII Lionel trains (that was what he did day after day for more than 60 years, in addition to running his train manufacturing companies) and was well aware of the problem. He said keeping the metal painted retarded the corrosion process but would not stop it completely, so I have to believe him. Thanks for that John, that's good information. They probably had to avoid lead based paint too, back in the day... |

|

|

|

Post by talltim on Oct 20, 2015 15:14:54 GMT -8

|

|

|

|

Post by WP 257 on Oct 20, 2015 17:54:52 GMT -8

Wow--that's absolutely amazing that it could "grow" that much and yet maintain some integrity, without displaying the cracks or outright breaking the frame first, due to the weakening of the metal.

John

|

|

|

|

Post by es80ac on Oct 20, 2015 18:51:37 GMT -8

The first run QJ had a middle driver that is slightly smaller than the others. It is quiet noticeable, Bachmann's stupid way of avoiding the electric short as the loco is traveling through the frog of a turnout. The size difference I heard is also causing excessive wear on the valve linkage and lead to problems down the line as well. I have a one of these from the first run that' been sitting on the shelf for many years. The later run QJ have full size middled driver that is either having a flange (not present on the real thing) or still a little undersized but less noticeable middle driver. The price of these locomotives have gone through the roof in China. When they first came out Trainworld was selling them at 150 dollars, the new ones are selling for 2600 rmb minimum plus which is about 430 dollars not including shipping.

|

|

|

|

Post by lvrr325 on Oct 21, 2015 13:03:10 GMT -8

Varney stuff from around 1961 suffered this frequently. They did a run of docksides in bright colors which are virtually impossible to find intact. But yet older and newer plain black ones turn up that run fine.

Somewhere I have an AHM FT - which was also made by Kader or someone in Hong Kong with a similar drive to the early Bachmann engines - which did the same as in the link, the frame is longer. But here the shell contained it some and it warped downward as well. It's amazing what force there is in that little bit of a reaction.

|

|