|

|

Post by fr8kar on Mar 30, 2016 11:50:32 GMT -8

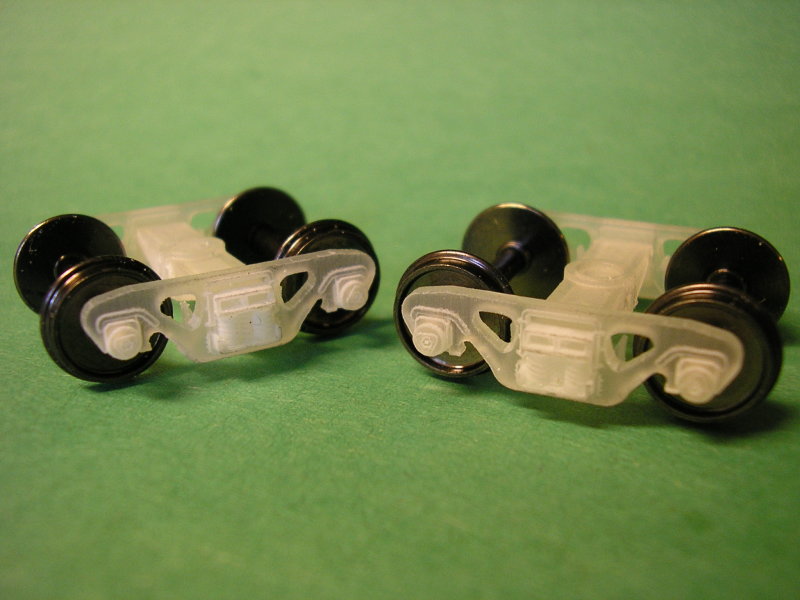

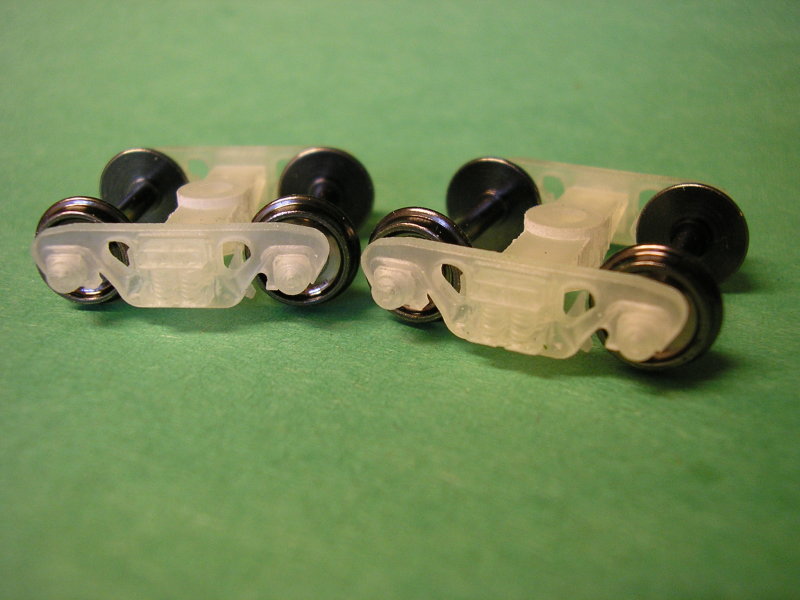

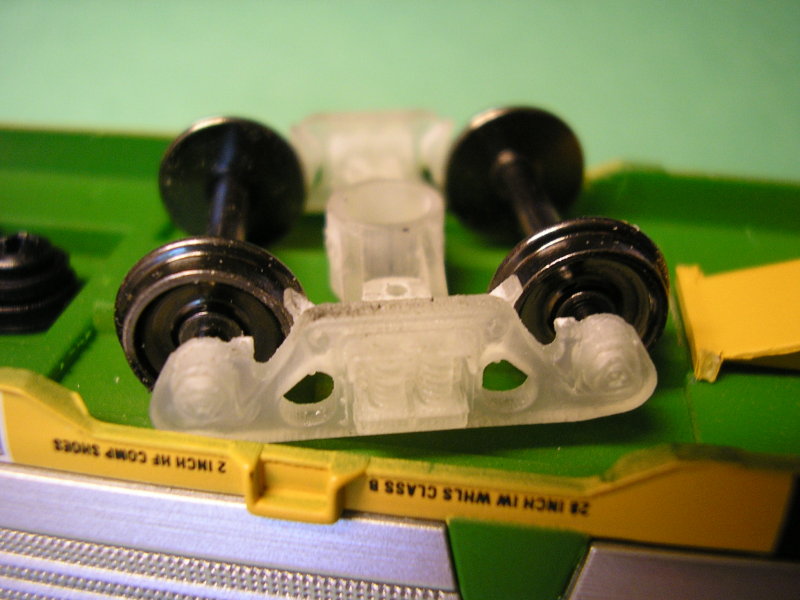

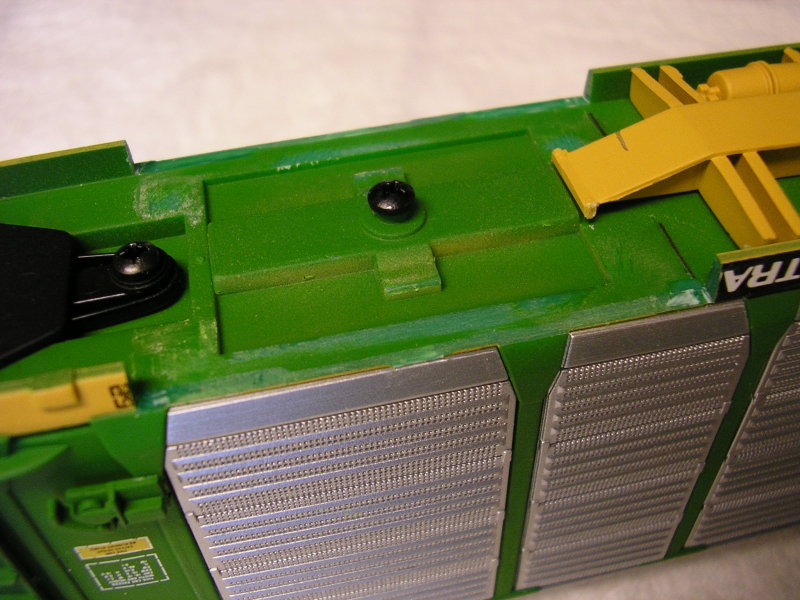

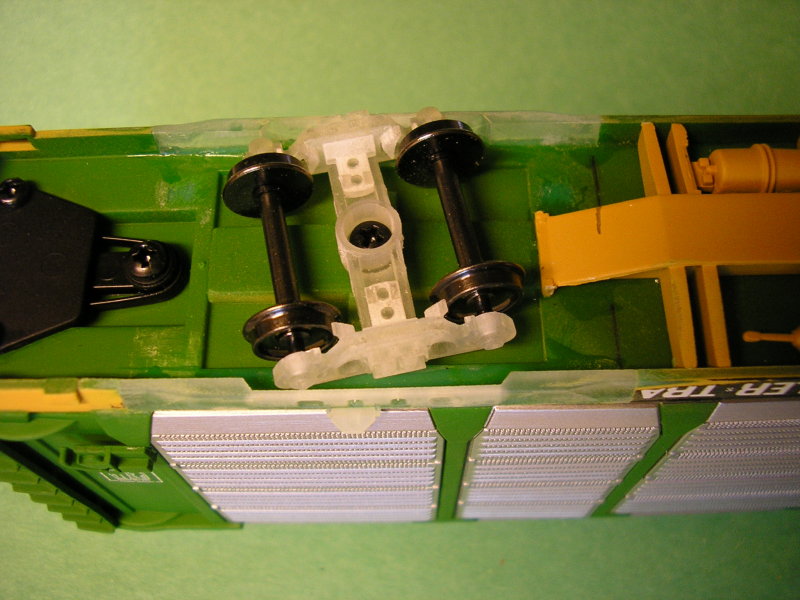

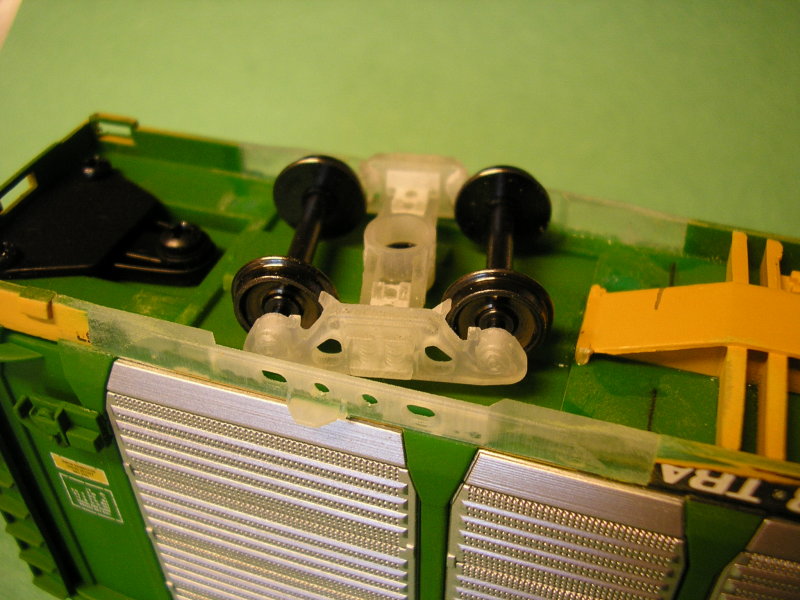

Here are some items I got from Shapeways a couple days ago. First, National Swing Motion trucks, 70-ton, 33" wheels, 6 spring pack version:     Next, National Swing Motion trucks, 70-ton, 33" wheels, 8 spring pack version:    The 8 spring pack version was used on UP's CA-11/CA-11M class cabooses. Both versions are used extensively on autoracks. A mixture of both kinds can be found on some spine cars with the ends having the 6 spring pack version and the articulated joints having the 8 spring pack version. I've also seen them on stand alone well cars. The 6 spring pack versions are also used on Roadrailers. For the low deck autoracks, here are some National Swing Motion 70-ton trucks with 28" wheels:    While on the subject of autoracks, I came upon this variation at work and shot it on my way home:   There are two major variations on this type of flat: unmodified, without inspection holes and modified with inspection holes and a reinforcing plate. I've found two versions of the reinforcing plate so far. Here is what I came up with to model this variation:   Modification to the Walthers trilevel autorack:  Part installed:   Painted to match:     |

|

|

|

Post by fr8kar on Mar 30, 2016 12:00:12 GMT -8

|

|

|

|

Post by fr8kar on Mar 30, 2016 12:05:44 GMT -8

|

|

|

|

Post by kentuckysouthernrwy on Mar 30, 2016 12:56:58 GMT -8

Nice to see some real innovative modeling going on. Nice job Ryan.

What is the truck model? We don't see much 4 axle equipment like that around this area. Looks like a Freightliner cab.

|

|

|

|

Post by fr8kar on Mar 30, 2016 14:21:42 GMT -8

Thanks, Karl. In 2008, Truck Stop Models sponsored an HO scale model building contest where entrants would choose a prototype photo from Hank's Truck Pictures Lunchtime at the Overpass photo collection. I chose this photo for my prototype:  This is the model I built from the photos, starting with an Athearn Freightliner:  There are more photos, including the photos from the build here: www.pbase.com/mecrharris/lunchtimeOther prototype photos I found on Hank's site of the same truck (or other similar trucks operated by the same company) showed various loads of precast concrete storm drainage structures. I made some pipe out of styrene tube and loaded the truck with that, but I was never happy with it. I've since designed some bell-end pipe loads along with other precast structures such as inlets and these junction boxes. I worked for a long time in civil engineering, so I'm very familiar with these types of structures. If there's demand for them, I'll continue to create more drainage structures for my Shapeways store. |

|

|

|

Post by onequiknova on Mar 30, 2016 14:37:30 GMT -8

Nice looking stuff! I really want to learn how to draw in 3D.

|

|

|

|

Post by fr8kar on Mar 30, 2016 14:52:43 GMT -8

Thanks, John. If I were to start over, this free software is very intriguing to me: www.onshape.com/Plenty of other programs out there, free and pay software. But you can get started with some pretty basic stuff. I still use AutoCAD, though. |

|

|

|

Post by drolsen on Mar 30, 2016 18:30:25 GMT -8

Ryan, that's awesome work! I have to look at those trucks some more to get a better understanding of their spotting features. Prototype trucks are something I haven't paid enough attention to in order to mode the correct type on a given freight car (aside from matching the correct weight, spring configuration, and general shape). The autorack side sills are fantastic as well! I will definitely need to model one of those. Thanks for making your designs available to others!

Dave

|

|

|

|

Post by fr8kar on Mar 30, 2016 19:44:12 GMT -8

Thank you, Dave. The key with these swing motion trucks is the thin U-shaped transom underneath the spring groups. You can see it just below the handbrake rod in my second prototype photo. It is what allows these trucks to absorb side-to-side motion, which is what makes them ideal for sensitive or damage-prone loads. I have yet to draw the 38" wheel version that are used on Amtrak reefers, but they're on the list: www.hebners.net/Amtrak/amtREEF/amt74077e.jpgThanks for the comment on the sill parts for the PLH21 and PLH21A flatcars. I'm pretty happy with how well they fit the Walthers model. When I get a little more time I'd like to work on replacement doors for the Walthers autoracks as well. |

|

|

|

Post by stevef45 on Mar 30, 2016 20:20:16 GMT -8

Some nice clean stuff too, don't see any printing lines. What is your shapeways store link?

|

|

|

|

Post by fr8kar on Mar 30, 2016 20:57:11 GMT -8

It's in my signature, Steve, but if it doesn't show up for you (I don't see it on my phone), it's: www.shapeways.com/shops/he6agonThe key to avoiding printing lines is orientation of the part. It's not always predictable what Shapeways will do with a given part, but with a little trial and error I've begun to get some consistent results. Jeff, thanks for your enthusiastic response! That's how I feel about it, too. It really is a new medium, like building in plastic, wood or brass and for me it's like when I discovered building in styrene after cutting my teeth on strathmore board (anyone remember that stuff?). And unlike resin casting, undercuts are possible. For example, the four coil springs on each side of the Uni-Truck II are full coil springs, not half cylinders, and the spring detail isn't fudged to allow the part to exit the mold. This is impossible with resin casting or injection molding. As far as the knowledge is concerned, well that's in large part due to the knowledge of coworkers at the diesel shop and in the car barn along with some very knowledgeable and generous modelers out there. Old magazines from the early 90s on back can be very helpful when it comes to drawings. Model Railroader of the 1980s bears almost no resemblance to the product they publish today. Another really good resource for me has been the Car & Locomotive Cyclopedia. But there's nothing like getting up close to the real thing and seeing it for yourself if you can. I'm very hopeful you guys and others can get started making your own parts, whether its with Shapeways, another printing bureau, a public library or with your own printer. I take nothing away from the Athearns, Atlases and Scale Trains of the world who dig deep in their own pockets to research, finance and create some great projects for us to nitpick over. But the advent of great 3D printing, when it arrives, will democratize the research, design and production of models and with a different set of rules than the current methods of manufacturing allow. Things that weren't possible will be possible. It's very exciting and my models are just a tiny glimpse of that possibility. There are some really skilled modelers out there just waiting to be discovered. And some models that previously had absolutely zero chance of being done in plastic or even brass will be available. |

|

|

|

Post by GP40P-2 on Mar 30, 2016 21:04:31 GMT -8

Thanks, John. If I were to start over, this free software is very intriguing to me: www.onshape.com/Plenty of other programs out there, free and pay software. But you can get started with some pretty basic stuff. I still use AutoCAD, though. Thanks for sharing this. It might be the push for me or someone else on here to try it out, and see what we can come up with. There are so many possibilities with many different people working on various projects. Just scrolling through what comes up when you search "HO" on Shapeways is unbelievable in the variety of hits that you get! Jim |

|

|

|

Post by fr8kar on Mar 30, 2016 21:25:42 GMT -8

Thanks, John. If I were to start over, this free software is very intriguing to me: www.onshape.com/Plenty of other programs out there, free and pay software. But you can get started with some pretty basic stuff. I still use AutoCAD, though. Thanks for sharing this. It might be the push for me or someone else on here to try it out, and see what we can come up with. There are so many possibilities with many different people working on various projects. Just scrolling through what comes up when you search "HO" on Shapeways is unbelievable in the variety of hits that you get! Jim My pleasure, Jim. I hope you're right and people do try it out. As soon as I get a new computer I will. I'm currently running AutoCAD r15 on an old WinXP machine and I do my internet browsing on a little netbook. Long past time to upgrade, but it still works! I've been pushing Shapeways to add more categories and improve their search capability and so have several others. Right now it's like the old days using Boolean search terms to get any meaningful results. But, I'd rather they perfect the actual printing and quality control of the product than focus on the browsing experience, if it's got to be one or the other. There's plenty of room for improvement in the printing of FUD and FXD materials, especially when it comes to print orientation. They're beta testing a method for setting orientation for other materials right now, but unfortunately it doesn't include FUD or FXD. I have several models that are awaiting consistent enough printing for me to roll the dice on the models. Right now I am not willing to risk dropping a couple hundred bucks on a lump of unusable plastic, especially if it prints successfully once but I can't repeat the quality with successive orders (which is how things are now). I agree with you about the variety and quality of HO scale models available already. It's impressive and things will only get better. |

|

|

|

Post by onequiknova on Mar 30, 2016 21:34:15 GMT -8

Thanks, John. If I were to start over, this free software is very intriguing to me: www.onshape.com/Plenty of other programs out there, free and pay software. But you can get started with some pretty basic stuff. I still use AutoCAD, though. Thanks for sharing this. It might be the push for me or someone else on here to try it out, and see what we can come up with. There are so many possibilities with many different people working on various projects. Just scrolling through what comes up when you search "HO" on Shapeways is unbelievable in the variety of hits that you get! Jim Shapeways needs to fix their search feature. It's useless. I just tried searching for "HO scale swing motion trucks". 33,000 results of completly unrelated items, and Fr8kar's trucks no where in sight. I've tried finding stuff on their site in the past that I know exist, but ussually just give up. |

|

|

|

Post by stevef45 on Mar 30, 2016 21:58:25 GMT -8

It's in my signature, Steve, but if it doesn't show up for you (I don't see it on my phone), it's: www.shapeways.com/shops/he6agonThe key to avoiding printing lines is orientation of the part. It's not always predictable what Shapeways will do with a given part, but with a little trial and error I've begun to get some consistent results. Thanks, couldn't see that small font due to works computers. You should make that brake rigging jig into a 3D part!! |

|

|

|

Post by fr8kar on Mar 30, 2016 22:21:14 GMT -8

Thanks for sharing this. It might be the push for me or someone else on here to try it out, and see what we can come up with. There are so many possibilities with many different people working on various projects. Just scrolling through what comes up when you search "HO" on Shapeways is unbelievable in the variety of hits that you get! Jim Shapeways needs to fix their search feature. It's useless. I just tried searching for "HO scale swing motion trucks". 33,000 results of completly unrelated items, and Fr8kar's trucks no where in sight. I've tried finding stuff on their site in the past that I know exist, but ussually just give up. You are preaching to the choir! If you use the operator AND between swing and motion you will get some better results. Using quotes around "swing motion" does nothing, even though I included the tag "swing motion" in the product listing. It's beyond ridiculous and something I thought we left behind in the internet of the '90s with drop shadows, scrolling text and bad MIDI music. But again, I'd rather have good, consistent parts than easy searches if it's one or the other. |

|

|

|

Post by fr8kar on Mar 30, 2016 22:22:41 GMT -8

It's in my signature, Steve, but if it doesn't show up for you (I don't see it on my phone), it's: www.shapeways.com/shops/he6agonThe key to avoiding printing lines is orientation of the part. It's not always predictable what Shapeways will do with a given part, but with a little trial and error I've begun to get some consistent results. Thanks, couldn't see that small font due to works computers. You should make that brake rigging jig into a 3D part!! You talking about the HTC bending tool? I don't know if it would work or not, given the close clearance between walls on part of it, but I'll give it a whirl. |

|

|

|

Post by edgecrusher on Mar 31, 2016 5:33:51 GMT -8

Very cool,love what you've been doing. Any progress on the Rock Island bay windows?

|

|

|

|

Post by fr8kar on Mar 31, 2016 9:39:12 GMT -8

Very cool,love what you've been doing. Any progress on the Rock Island bay windows? Not yet. Life keeps getting in the way of a field trip. But it will happen. |

|

|

|

Post by csxt8400 on Mar 31, 2016 10:25:18 GMT -8

Fantastic stuff. Looks really nice. Would love to see a KATO six axle flexicoil sideframe with open bearings...  |

|

|

|

Post by wmpaul on Mar 31, 2016 11:32:14 GMT -8

Your Shapeways trucks are amazing. My question is, how are they going to hold up in operation? Is the plastic strong enough to hold up to the metal axle's rotation, or are the journals going to become egg shaped?

Paul B

|

|

|

|

Post by edwardsutorik on Mar 31, 2016 12:18:37 GMT -8

Your Shapeways trucks are amazing. My question is, how are they going to hold up in operation? Is the plastic strong enough to hold up to the metal axle's rotation, or are the journals going to become egg shaped? Paul B There are bearing inserts that will likely solve the problem, as long as they can be firmly stuck in place. I suppose that, since the part is being built, it would be easy to put little teeth, or knurling, in the edge of the hole where the insert goes. Ed |

|

|

|

Post by fr8kar on Mar 31, 2016 12:32:29 GMT -8

Fantastic stuff. Looks really nice. Would love to see a KATO six axle flexicoil sideframe with open bearings...  Thanks! That's a good suggestion. I've done some research on the triple clasp sideframes used on N&W U30C and C30-7 diesels, but haven't gotten far enough to put a drawing together yet. So, we're on the same page, I can tell you that! |

|

|

|

Post by fr8kar on Mar 31, 2016 12:38:02 GMT -8

Your Shapeways trucks are amazing. My question is, how are they going to hold up in operation? Is the plastic strong enough to hold up to the metal axle's rotation, or are the journals going to become egg shaped? Paul B That's a great question, Paul. I have to be honest, I don't know how they will hold up. And I don't really have a good testing track for that purpose. I thought about using the nylon plastic inserts that Tichy sells, but I didn't want to be constrained by having to ensure there was 0.024" thick plastic surrounding the insert since it would have made the bearings stick too far out and be too big around. I used Frosted Extreme Detail acrylic, and I'll only sell the parts in this material (or another material that comes down the line with greater strength and print resolution) so the parts are as strong as they can be. Maybe a little powdered graphite can provide enough lubrication to avoid wear. The only way to know is to test the parts and I've had them three days now so it's a little early for me to say! |

|

|

|

Post by nsc39d8 on Mar 31, 2016 13:41:21 GMT -8

Ryan,

I am in for a couple of sets of the GE triple clasps. I have a C30-7 and C36-7 that need them. I have built one set off the Atlas trucks. I am sure there are modelers that have the Atlas and Broadway Limited C30-7 that would want them. Might even need a set for a C39-8 down the road.

|

|

|

|

Post by roadkill on Mar 31, 2016 15:53:24 GMT -8

Fantastic stuff. Looks really nice. Would love to see a KATO six axle flexicoil sideframe with open bearings...  Thanks! That's a good suggestion. I've done some research on the triple clasp sideframes used on N&W U30C and C30-7 diesels, but haven't gotten far enough to put a drawing together yet. So, we're on the same page, I can tell you that! We could also use triple clasp HTC's and Flexicoils, too... hint, hint  |

|

|

|

Post by fr8kar on Mar 31, 2016 16:04:14 GMT -8

We could also use triple clasp HTC's and Flexicoils, too... hint, hint  I think Chris Howard has the HTC triple clasp trucks in his Shapeways store. I'm not sure if they fit the Athearn model without modification or not. I haven't messed around with them because I already built all I need from Athearn parts. |

|

|

|

Post by SCL618 on Apr 4, 2016 18:17:37 GMT -8

We could also use triple clasp HTC's and Flexicoils, too... hint, hint  EMD Flexicoil FC-2L side frames that fit Atlas SD trucks would be better than sliced bread in my book. Of the SD35s produced, 177 rode on these trucks with Southern Railway being the largest owner, followed by ACL, B&O, and N&W. EMD Flexicoil FC-2L |

|

|

|

Post by roadkill on Apr 5, 2016 7:20:25 GMT -8

EMD Flexicoil FC-2L side frames that fit Atlas SD trucks would be better than sliced bread in my book. Of the SD35s produced, 177 rode on these trucks with Southern Railway being the largest owner, followed by ACL, B&O, and N&W. EMD Flexicoil FC-2LI'd like a good triple clasp Flexicoil to get rid of the awful sideframes on the Atlas SD35, tho I wouldn't mind the FC-2L to do one of the 4 B&O units that had them. |

|

|

|

Post by roadkill on Apr 5, 2016 7:25:41 GMT -8

One question re: FED/FUD, how good is it for really fine detail? I'm in need of a few sets of the short inertial intake grille used on some GP35's and I'm wondering how well the fine screening would print. Thought about attempting to shorten the C&C GP35 inertial grilles but seeing as each grille would need 4 (!) cuts and splices my patience just won't allow it.

|

|