|

|

Post by sd40dash2 on Feb 16, 2019 8:04:35 GMT -8

Please post your in-progress photos showing consistent cuts to styrene strips along with photos of the tool you use to accomplish said cuts. Close-up modelling photos which show the installed parts are also welcome as a means of inspiration to anyone on the fence about spending the money on one of these tools. Lastly, your first-hand reviews and opinions about the tools you have personally used are also welcome. Are there any other competitively-priced chopper tools besides the following? NWSL Chopper I: NWSL Chopper II: NWSL Chopper II:

NWSL Chopper III: Micromark Chop It: Micromark Chop It: Thread on how to build your own improved chopper: www.rebelscale.com/2015/03/building-a-better-chopper/ |

|

|

|

Post by 12bridge on Feb 16, 2019 8:40:58 GMT -8

I have a love/hate relationship with my chopper. It is great for getting multitudes of smaller pieces consistent, but once you start doing anything bigger then about .030", you cant get a straight cut (atleast in Styrene) as the blade wants to walk sideways. But still, a very handy tool to have.

These days I do just about everything with USA made (it DOES make a difference) razor blades, using essentially a new one everyday.

|

|

|

|

Post by edwardsutorik on Feb 16, 2019 9:04:01 GMT -8

Photos? Not today.

I use my Chopper I on occasion. As mentioned above, it's good for multitudes of thin pieces.

For thicker, I use the cheap aluminum miter saw kit that everyone else has.

If I need that done accurately, I face the pieces off in my milling machine. As in, last night, with .250 x .750 Evergreen strip, at 1.320.

Ed

|

|

|

|

Post by fr8kar on Feb 16, 2019 10:17:35 GMT -8

I used a Chopper I to make several bridge shoes for a pair of highway bridges. The only photo I have handy is this one taken during construction:  If I remember correctly, I used 0.020" styrene strip, so I didn't have any issues with the blade wandering. I did periodically check the position of the guides though since they could walk a bit over time. For awhile I thought about making 3D files to print Southern Pacific's ACF well car, but I can't seem to get anything very large to print worth a damn from Shapeways. The more I think about it scratchbuilding in styrene would be the way to go. If I end up going that route, I'll surely put the Chopper to work again. |

|

|

|

Post by Paul Cutler III on Feb 16, 2019 10:43:09 GMT -8

I have a Chopper II, and I like it for what it is. It's accurate and square, but the fact that you can't get a chisel shaped blade is a common problem for all these kinds of Choppers. If we could get chisel blades, one side of the cut would be flat & square. But since all we can get are V-shaped blades, it means that with thicker stock, you end up having to sand (or file) the cut end to square it up...which kind of defeats the purpose of having a precise chopper.

Still, I'm glad I have the Chopper II. I much prefer it over the Chopper I that we have at our club. The Chopper I can get pretty loose at the joint, which can lead to cuts that are not square in two planes. Plus, the self-healing cutting mat on the Chopper II is superior to the Masonite on the Chopper I.

I would tend to avoid the cheaper Micro-Mark version of this tool. In my experience, the MM tools are less expensive for a reason; the knobs aren't as nice, the finish isn't as good, etc. I would spend the extra few bucks and get the NWSL version...they are just more pleasant to use.

|

|

|

|

Post by kentuckysouthernrwy on Feb 16, 2019 10:52:28 GMT -8

I have a Chopper II for several years, mostly used for wood here.

|

|

|

|

Post by slowfreight on Feb 16, 2019 11:04:25 GMT -8

I've been using the Chopper III for a couple of decades now. I, too, have trouble getting it to cut without the blade veering a bit on thicker material. I find that it matters how long the drop is that I'm cutting off. Longer parts cause the blade to shift less as I chop. Sometimes I can use jigs or fixtures to hold things more rigidly.

Getting straight, square parts is probably the most important step in making nice scratchbuilt stuff, and it can be challenging.

|

|

|

|

Post by Christian on Feb 17, 2019 3:02:47 GMT -8

I have a very early chopper I - back when there wasn't a chopper II. Primitive parts compared to the photo above of a current product. The failing then and now is the scrap of fiberboard that is the mounting surface. I replaced mine with a 3/8" piece of high-density particle board thirty? forty? years ago and it has been fine since. (HDF from your hardwood supplier.) That said, usually, I just use a single edge razor blade and freehand small numbers of cuts against a steel ruler. And a miter box and saw for thicker pieces. I'll drag out the chopper if I'm doing lots of identical cuts on stock up to 0.030". Miter box with a stop for thicker pieces.

|

|

|

|

Post by Donnell Wells on Feb 17, 2019 17:32:45 GMT -8

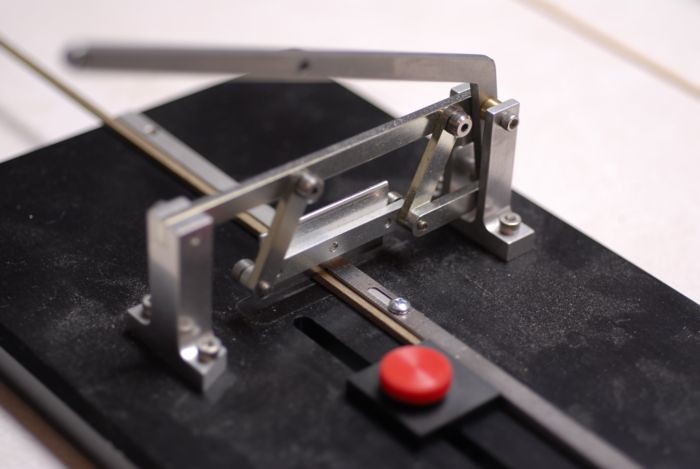

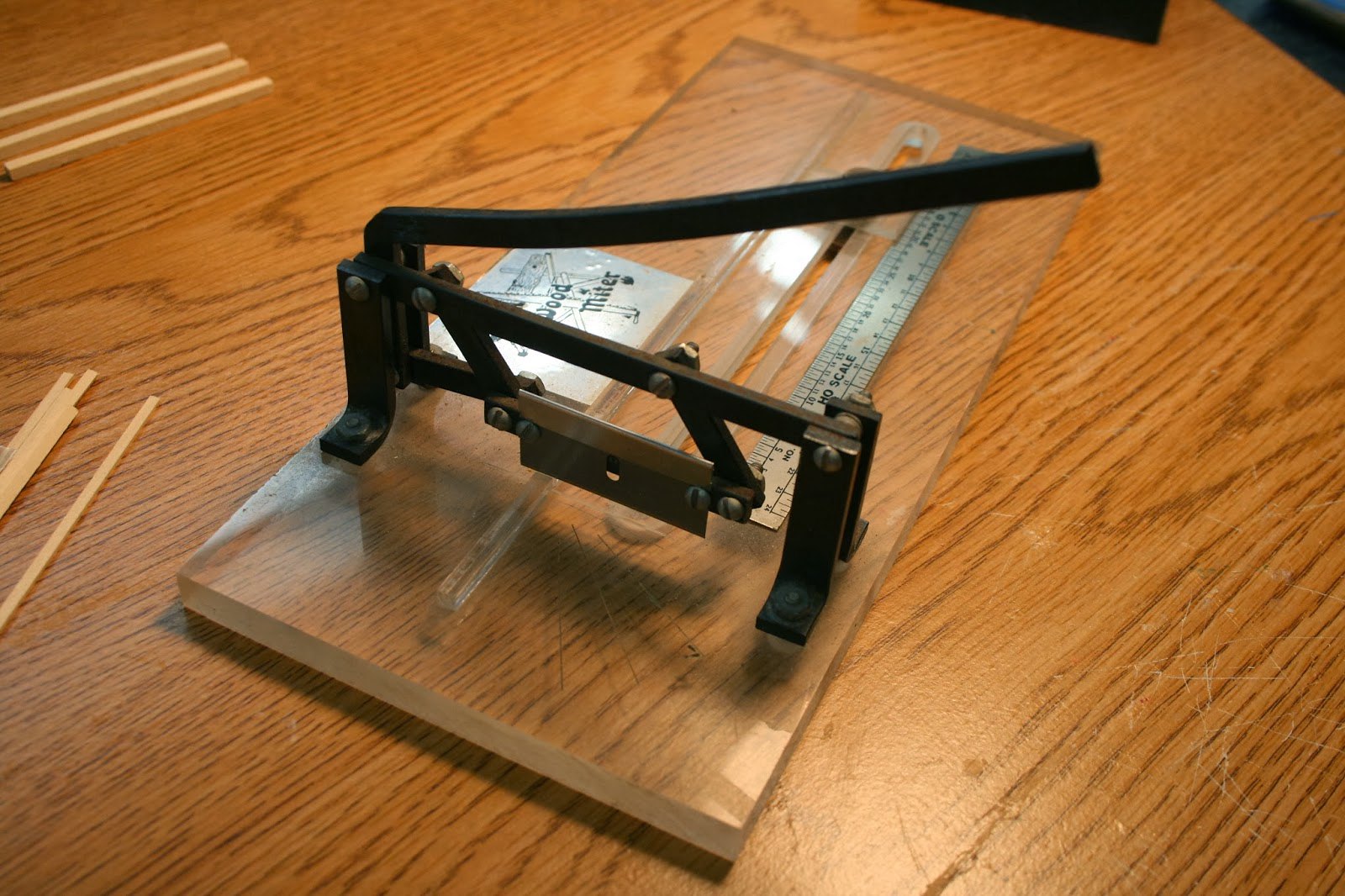

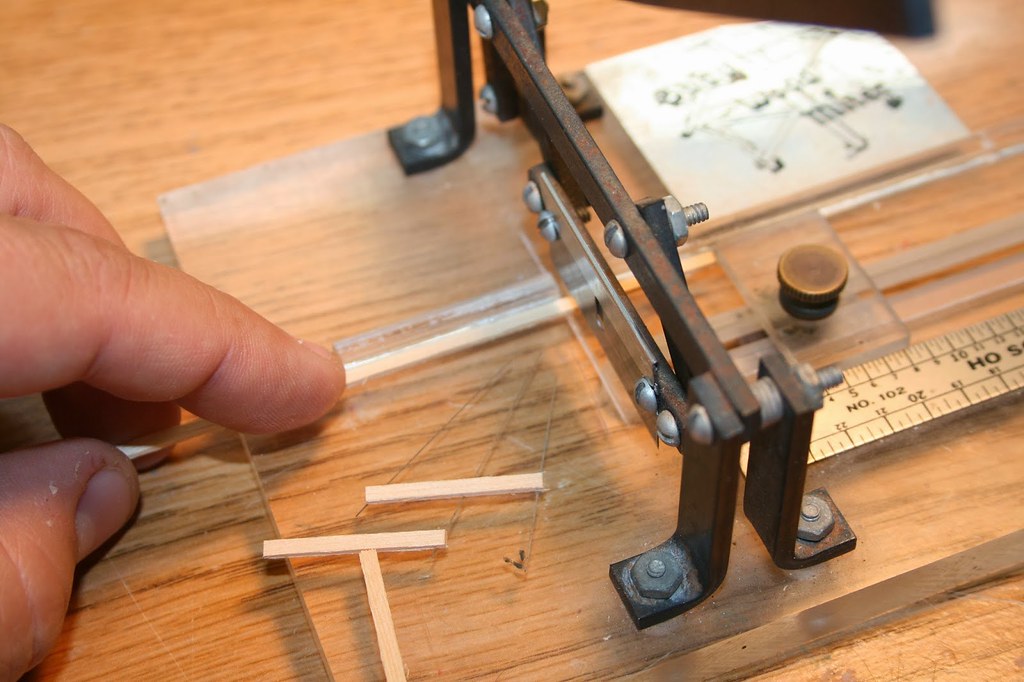

Since we're talking about choppers, let's not forget about the purported "Cadillac" of choppers, The Calibre Cutter as seen below:

The Calibre Cutter was based on an earlier (1975) cutter known as the Shay Wood Miter, seen below:

Neither cutter is currently in production. However, just looking a the pictures, I'm sure one could reverse engineer their own version if they felt motivated!

*Note* These are not my pictures, just ones I found during a Google search.

Donnell |

|

|

|

Post by csx3305 on Feb 17, 2019 18:56:04 GMT -8

I recently bought a Chopper 2 to repeat the cuts needed to make waffle side cars out of the Intermountain 5277. It looks and feels far superior to the earlier and later Masonite base versions, you have to wonder why they called a Mulligan on that design.

|

|

|

|

Post by slowfreight on Feb 18, 2019 6:49:08 GMT -8

It looks like the back rail and stops on the Chopper III are more precise than the Chopper II. So at a glance I would agree, but I use the back rail constantly.

I improved my Chopper III slightly by placing a styrene stop block under the swing arm so that it doesn't dig a deep groove in the masonite every time I cut.

|

|

|

|

Post by cannon on Feb 18, 2019 9:09:54 GMT -8

I have had two Shay Wood Miters, since Lonnie Shay (who was partner with the late Paul Scholes in the Little Depot in Buena Park back in the 70’s) first came out with it. Still use it all the time. The cool thing is the chopping action is parallel to the material not angular like the various Choppers. Pretty easy to set the adjustable stop with the depth rod of a pair if dial/digital calipers.

Dave Hussey

|

|

|

|

Post by sd40dash2 on Feb 19, 2019 17:40:54 GMT -8

Thanks everyone for your comments and photos. After considering all comments, it looks like the Chopper II is in my future. Will also look for the Made in USA blades.

|

|

|

|

Post by Colin 't Hart on Feb 20, 2019 0:06:28 GMT -8

|

|

|

|

Post by renaissanceman on Oct 18, 2022 12:38:51 GMT -8

I am in the process of building a Calibre Chopper. I am reverse engineering one, I borrow from a friend. I tried to add image 151k but it would not upload. I will try again another time.

|

|

|

|

Post by riogrande on Oct 18, 2022 15:09:47 GMT -8

I am in the process of building a Calibre Chopper. I am reverse engineering one, I borrow from a friend. I tried to add image 151k but it would not upload. I will try again another time. Use a photo host to post the picture. |

|

|

|

Post by lvrr325 on Oct 19, 2022 19:12:04 GMT -8

I have a Chopper, but it's still in the package.

There's a guy who consistently comes to the market late, like 11:45 late, by then some vendors have left already. He always has stuff priced to sell. So he had it. I think I paid a dollar and a half.

|

|

|

|

Post by Gino Damen on Oct 29, 2022 12:00:59 GMT -8

|

|